Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

The MT-series through conduit knife gate valve has a rectangular disc with a circular opening equal to the full-area flow passageway of the knife gate valve. By lowering or raising the disc, the opening is exposed to the flow or the blind barrier shuts off the flow, respectively. The through-conduit design allows the seating surfaces of the disc to be in close contact with the seat ring at all times. It eliminates any cavity or dead place in the valve body and there is no place for residue buildup, reducing the risk of blockage and contamination. With a full-bore opening, it eliminates turbulence and pressure drops, resulting in minimal flow resistance, and it also allows the use of a pig to clean the inside diameter of the line.

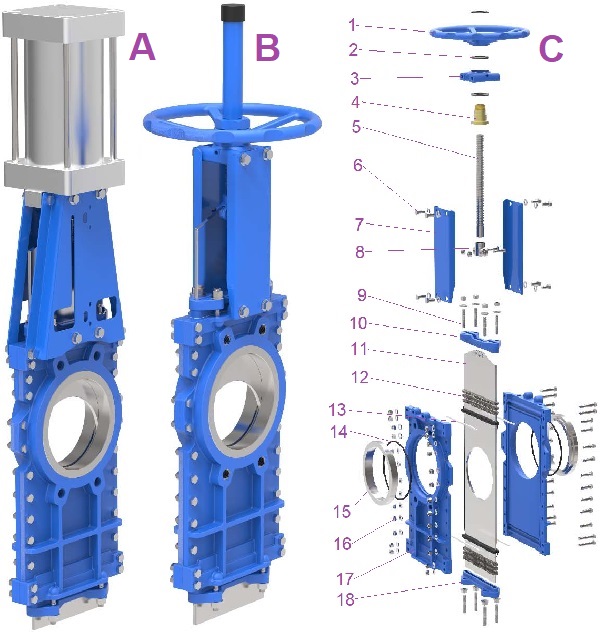

The illustration of MT-series through conduit knife gate valves. A: pneumatic actuated; B: handwheel operated; C: 3D explosive view of a MT-series rising-stem knife gate valve.

The MT-series through conduit knife gate valves are furnished with two-piece body in rectangular shape. The two halves of the valve body are cast separately and bolted up subsequently. A pair of metal retainers compress the soft seat rings firmly against the disc from two sides of the disc. This provides bidirectional shutoff capability, which makes them ideal for applications where flow direction may be reversed. A pair of scrapers are provided at the upper position of the body, along with the through-conduit design, imparting self-cleaning capability to the disc. The MT-series through conduit gate valve reduces the number of parts and the complexity of the valve, making it easier to maintain and reducing the risk of failure.

| Part No. | Part Name | Material Grade |

|---|---|---|

| 1 | Handwheel | GGG40, WCB |

| 2 | Bearing | ZChSnSb10-6 |

| 3 | Yoke Head | GGG40, WCB |

| 4 | Stem Nut | Brass |

| 5 | Stem | 2Cr13, SS410 SS304, SS316 |

| 6 | Bolt & Nut | SS201/ SS304 |

| 7 | Yoke | Mild Steel SS304 |

| 8 | Chuck | SS304, SS316 |

| 9 | Bolt & Nut | SS201/ SS304 |

| 10 | Packing Gland | GGG40, WCB CF8, CF8M CF3, CF3M |

| 11 | Disc | SS304, SS304L SS316, SS316L Duplex 2205 A182 F53, F55 |

| 12 | Packing | PTFE, NBR |

| 13 | Scraper | PTFE |

| 14 | Seat Ring | EPDM, NBR |

| 15 | Retainer | SS304, SS316 |

| 16 | Bolt & Nut | SS201/ SS304 |

| 17 | Body | GGG40, WCB CF8, CF8M CF3, CF3M Duplex 2205 |

| 18 | Packing Gland | GGG40, WCB CF8, CF8M CF3, CF3M |

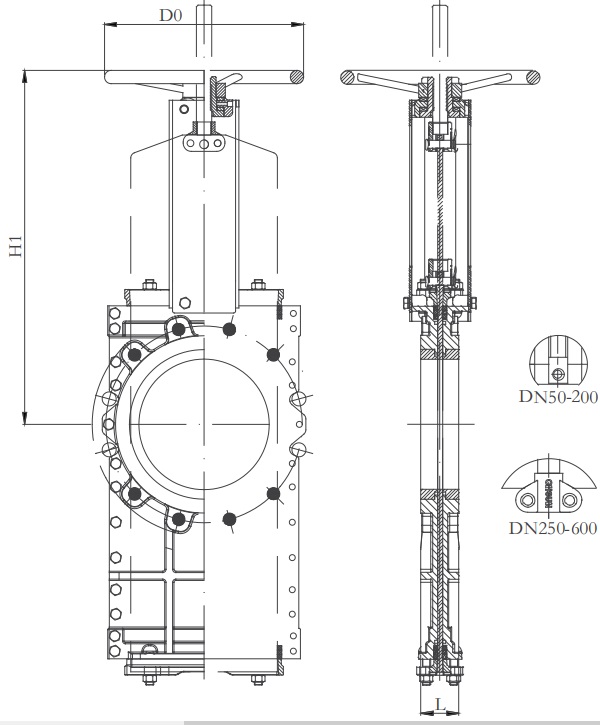

The G.A. drawing for a typical MT-series through-conduit knife gate valve with rising stem and handwheel actuation.

| Size | L | H1 | D0 |

|---|---|---|---|

| 2" | 48 | 260 | 180 |

| 2.5" | 48 | 292 | 200 |

| 3" | 51 | 320 | 200 |

| 4" | 51 | 358 | 240 |

| 5" | 57 | 395 | 260 |

| 6" | 57 | 450 | 280 |

| 8" | 70 | 532 | 300 |

| 10" | 70 | 670 | 320 |

| 12" | 76 | 758 | 350 |

| 14" | 76 | 857 | 400 |

| 16" | 89 | 946 | 450 |

| 18" | 89 | 1023 | 500 |

| 20" | 114 | 1250 | 500 |

MT-series through-conduit knife gate valves are commonly used in applications where a full bore, unobstructed flow path is required, as well as in situations where there is a risk of solid particulates or slags accumulating in the valve body or where the fluid is high-density viscous slurries. They are especially suitable for fluid medium such as coal mine, cement slurry, gold ore powder, mineral sand, wood pulp, tailings, fibers, dust, sediment, asphalt, fruit juice, grains, slaughterhouse wastewater, etc.