Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

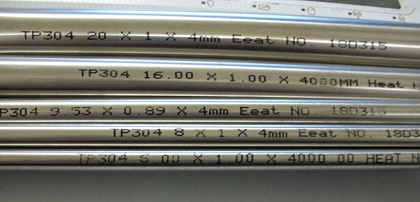

Various sizes of SAE J3129 seamless ss304 tubing, made of ASTM A269 Gr. TP304.

SAE J3129 is the standard released by Society of Automotive Engineers to standardize stainless steel bulk tubing. Seamless 304/304L stainless steel tubing manufactured in accordance with this standard is intended for use as hydraulic lines and in other applications requiring corrosion resistance.

The seamless tubing shall be made from stainless steel conforming to the chemical composition of S30400 or S30403 as specified in ASTM A269. The SAE J3129 seamless SS304/304L tubing shall be cold drawn and annealed to produce a finished product and shall meet all requirements of ASTM A269. After production is finished, tubes shall be bright annealed and passivated. Oxide annealed, pickled, and passivated can be supplied by agreement between producer and purchaser. Centerless grinding is not permitted; however, a light polish to improve surface appearance is permitted. Polished tubing must be subsequently passivated.

| Element | TP304, % | TP304L, % |

|---|---|---|

| C | ≤0.08 | ≤0.035 |

| Mn | ≤2.00 | ≤2.00 |

| P | ≤0.045 | ≤0.045 |

| S | ≤0.030 | ≤0.030 |

| Si | ≤1.00 | ≤1.00 |

| Ni | 8.0-11.0 | 8.0-12.0 |

| Cr | 18.0-20.0 | 18.0-20.0 |

| Properties | Values |

|---|---|

| Yield Strength, min. MPa | 205 |

| Ultimate Strength, min. MPa | 515 |

| Elongation in 50 mm, min. % | 35 |

| Rockwell Hardness, max. HRB | 90 |

| NOM1 inch | NOM2 mm | NOM3 mm |

|---|---|---|

| 0.250 | 6.35 | 6 |

| 0.312 | 7.94 | 8 |

| 0.375 | 9.52 | 10 |

| 0.500 | 12.70 | 12 |

| 0.625 | 15.88 | 16 |

| 0.750 | 19.05 | 20 |

| 0.875 | 22.22 | 22 |

| 1.000 | 25.40 | 25 |

| 1.250 | 31.75 | 30 |

| 1.500 | 38.10 | 38 |

| 2.000 | 50.8 | 50 |

The seamless ss 304/304L tubing may be furnished in several conventional sizes depending on “nominal inch tube OD, inch” – (NOM1), “nominal inch tube OD, mm – (NOM2) or “nominal metric tube OD, mm” – (NOM3), respectively. The tolerances applicable to the tubing outside diameter are shown in the table below.

| Nom. Tubing OD mm | Tolerance ±mm |

|---|---|

| OD≤12.7 | 0.08 |

12.7| 0.10 |

|

25.4| 0.15 |

|

50.8| 0.18 |

|

63.50| 0.20 |

|

76.20| 0.25 |

|

88.90| 0.38 |

|

The seamless ss 304/304L tubing manufactured in accordance with SAE J3129 shall satisfactorily meet the following performance tests according to ASTM A1016: flattening test, flaring test, reverse flattening test, tensile test, elongation test, pressure proof test, eddy current test, and ultrasonic test.

The tubes shall be straightened to a tolerance of 1 mm over a 1000 mm length. Finished tubes shall have smooth end free of burrs. The surface condition of the tube is critical in order to prevent possible leak paths on double flare fittings, mechanical form fittings, or other applications where the outside or inside surface of the tube becomes the sealing surface. The surface of the tube shall be free of excessive roll marks, score marks, chatter marks, or the other surface imperfections that are considered detrimental to the function of the tubing. The tubing may be packaged in straight lengths or coils, in sea-worthy firm plywood cases.