Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

The slip type expansion joint is a tubular piping expansion joint. It is also known as sleeve expansion joint or sleeve compensator. There is also a famous proprietary brand of slip expansion joint commercially available in market: Dresser® Style expansion joint. Slip type expansion joints are particularly suited for lines having straight-line (axial) movements of large magnitude. They cannot tolerate lateral offset or angular rotation (cocking) since it would cause binding, galling, and possibly leakage due to packing distortion. Therefore, slip expansion joints are usually used with proper pipe guides to ensure the alignment. Nowadays they are widely used in district heating systems and civil water supply piping.

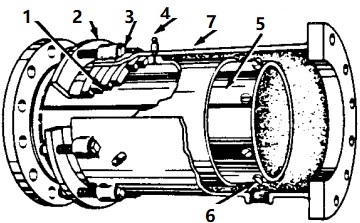

The slip type expansion joint generally consists of sliding sleeve, tubular body, packing material, packing gland, gland bolting, lubrication fitting, injection cylinder & plunger, etc. As illustrated in Figure-1, the sliding sleeve telescopes into the body. When connected piping expands or contracts, the sleeve slides axially along the body’s internal surface to absorb the piping movements. The sealing performance is determined by packing materials located between the sleeve and the body (the space between the sleeve and the body to accommodate packing is called stuffing box). The packing may be prefabricated O rings & Y rings, or injectable flexible flake graphite, etc.

Figure 1: illustration of a typical slip expansion joint: 1. packing; 2. packing gland; 3. gland bolting; 4. lubrication fitting; 5. sliding sleeve (slip); 6. limit stop; 7. body.

The packing gland is provided to compress the packing by tightening its bolting. Packing materials are constrained within the stuffing box. Lubricants are injected through the lubrication fittings to reduce the friction between the packing and the body, therefore improving wear resistance of packing materials. In some cases, the packing materials can be replenished into the stuffing box through an injection nozzle – plunger. With injection plungers, the slip joints are usually called gun-packed or ram-packed expansion joints. The limit stop pins are designed to prevent disengagement of the sleeve from the stuffing box in the event of extreme piping expansion. All the stop pins are welded in place.

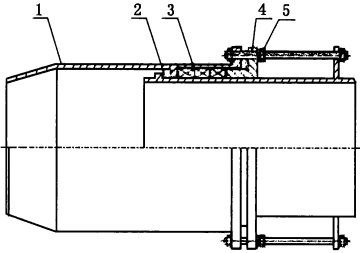

Figure-2: flange connection and butt welding connection slip type expansion joints.

Shijiazhuang Metalsin Pipeline Tech Co., Ltd can supply various types of slip type expansion joints, which have been certified to be steam leak-free for 32,000 cycles while pressurized at 2.5 MPa saturated steam. We offer a 6-year leak-free warranty on all slip expansion joints provided. Generally, the maximum design temperature is 200°C for hot water system and 350°C for steam line. The nominal diameter of the joint can be up to DN 1400. Of course, custom-design is also available according to client’s specific requirements.

Both the body and the sliding sleeve (slip) are generally machined from ASTM A106 Grade B seamless pipe or equivalent materials. Especially, the surface of the sliding sleeve is machined and ground and subsequently chromium plated to obtain excellent wear resistance and corrosion resistance. The packing rings shall be made of natural or synthetic rubbers. Injected packing materials are often flexible graphite. The gland flanges are usually made from ASTM A105 or equivalent carbon steel materials, while the bolting materials are ASTM A193 B7/ ASTM A194 2H. The limit stop pins are usually made of high strength alloy steels. Since modern packing materials are usually low-friction or self-lubricated, the lubrication fittings are not required. The injection cylinder and plunger may be made from carbon steel, stainless steel or aluminum bronze depending on specific applications.

The drawing of a single slip expansion joint with unidirectional flow.

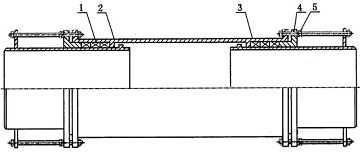

Slip type expansion joints can be simply classified as flange end or butt welding end depending on its end connection type. According to the flow directions it allows, the joint can also be classified as single slip expansion joint and double slip expansion joints. According to the packing method it adopts, slip expansion joints can be classified to rubber-ring packed type, injected-packing type, or composite packing type. Further, the slip expansion joints may be furnished in directly-buried type, non-thrust type, bypass type, as well as prefabricated thermal insulation type.

The drawing of a double slip expansion joint permitting bidirectional flow.

| Nominal Size DN | Maximum Designed Compensation Rate (mm) |

|

| For Hot Water | For Steam | |

| 50~65 | 160 | 220 |

| 80~125 | 160 | 275 |

| 150~300 | 230 | 330 |

| 350~500 | 320 | 440 |

| 600~1400 | 360 | 440 |