Design Characteristics

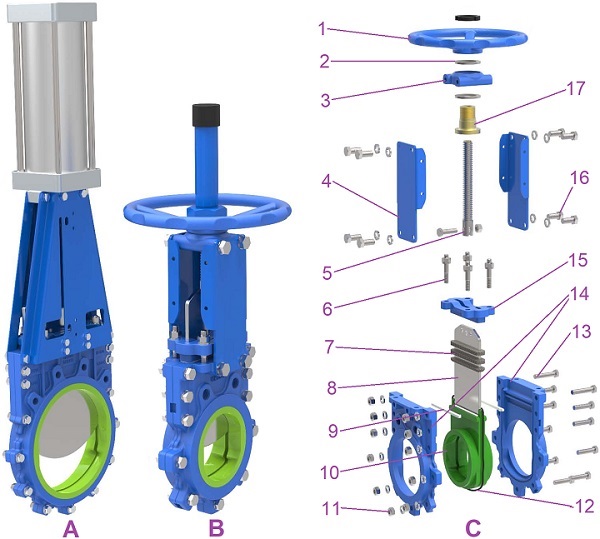

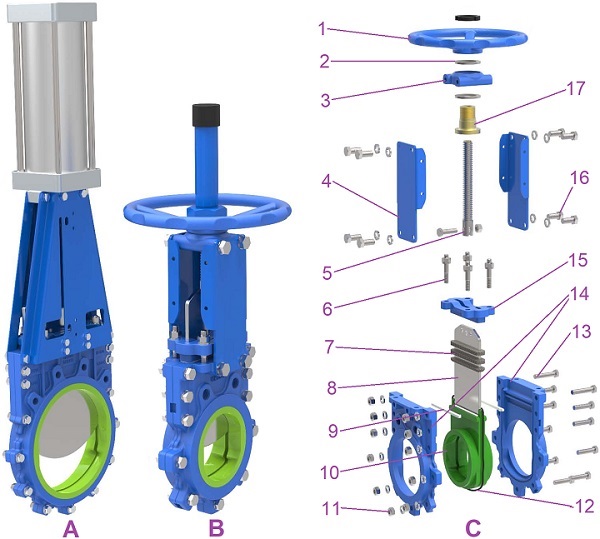

The illustration of MP-series polyurethane lined knife gate valves. A: pneumatic actuated; B: handwheel operated with rising stem; C: 3D explosive view of the PU lined knife gate valve.

The MP-series polyurethane lined knife gate valves we supply have the following distinctive design characteristics:

- Polyurethane lining: An integral polyurethane liner shall be prepared by cutting it to the correct size and shape for the valve body cavity. It is mounted properly in the valve body cavity to isolate the body from contacting the fluid. The polyurethane liner has excellent abrasion resistance and wear resistance, as well as good corrosion resistance to a wide range of chemicals. This makes it ideal for applications where there is a high level of abrasion and/or corrosion present, and where reliable and long-lasting performance is required.

- Two-piece body design: The MP-series PU knife gate valve is constructed by two separate half valve bodies that are bolted together. The two half bodies compact the polyurethane liner firmly within the body cavity, properly aligned and centered. This construction allows for easier maintenance and repair.

- Resilient seat & bidirectional flow: It resembles the MR-series. A resilient U-type seat ring is fitted in the preformed groove of the polyurethane liner. When the disc is moving down or up, the resilient seat is compacted into the groove or bouncing back to be level with the groove. No residual fluid will be retained by the body cavity and self-cleaning of the flow passage is achieved. The possibility of clogging will be reduced. Due to its resilient seated design, bidirectional installation is applicable providing greater flexibility and versatility for flow control.

- Disc scrapers: A pair of scrapers will be furnished to remove the slurries or solid particulates from the disc, ensuring good sealing performance and smooth on-off operation of the valve.

Material Selection

| Part No. | Part Name | Material Grade |

| 1 | Handwheel | GGG40, WCB |

| 2 | Bearing | ZChSnSb10-6 |

| 3 | Yoke Head | GGG40, WCB |

| 4 | Yoke | Mild Steel

SS304 |

| 5 | Stem | 2Cr13, SS410

SS304, SS316 |

| 6 | Bolt & Nut

(for Gland) | SS201/ SS304 |

| 7 | Packing | PTFE, NBR |

| 8 | Disc | SS304, SS304L

SS316, SS316L

Duplex 2205

A182 F53, F55 |

| 9 | Scraper | PTFE |

| 10 | Seat Liner | Polyurethane |

| 11 | Body Nuts | SS201/ SS304 |

| 12 | U-type Seat | EPDM, NBR |

| 13 | Body Bolt | SS201/ SS304 |

| 14 | Body | GGG40, WCB

CF8, CF8M

CF3, CF3M

Duplex 2205 |

| 15 | Packing Gland | GGG40, WCB

CF8, CF8M

CF3, CF3M |

| 16 | Bolt & Nut

(for Yokes) | SS201/ SS304 |

| 17 | Stem Nut | Brass |

*Available sizes from DN50 to DN800. For valve part details, please refer to illustration-C above. If you need a quote or structural & drilling dimensions of the MP-series knife gate valve, please feel free to

contact us.

Applications & Temperature Limits

The MP-series polyurethane lined gate valves is highly resistant to wear and tear and it is well-suited to applications where abrasive slurries or slags are being handled. Some specific applications of these valves include:

- Mining industry: They are often used in mining applications where there is a high level of abrasive materials present, such as coal, sand, and gravel. They are ideal for use in slurry transport systems, tailings management, and mineral processing applications.

- Wastewater treatment plants: The MP-series are commonly used in wastewater treatment plants for applications such as sludge handling, dewatering, and chemical dosing. They are resistant to corrosion from various chemicals used in the treatment process, such as chlorine and sulfuric acid.

- Power generation: The MP-series are often used in power generation applications, particularly in coal-fired power plants. They are resistant to abrasion and corrosion from the coal ash and other materials present in the flue gas and ash handling systems.

- Pulp and paper industry: They are used in the pulp and paper industry for applications such as wood chip handling, pulp stock, and black liquor handling. They are resistant to abrasion from wood chips and other materials present in the process.

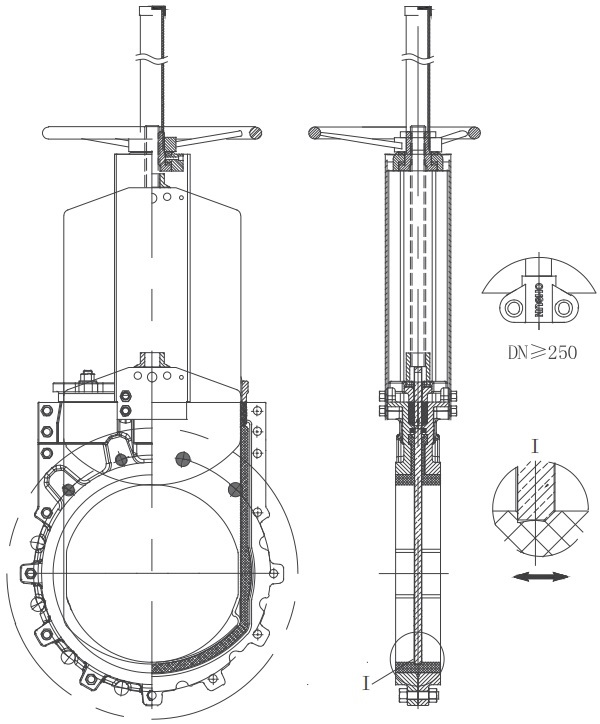

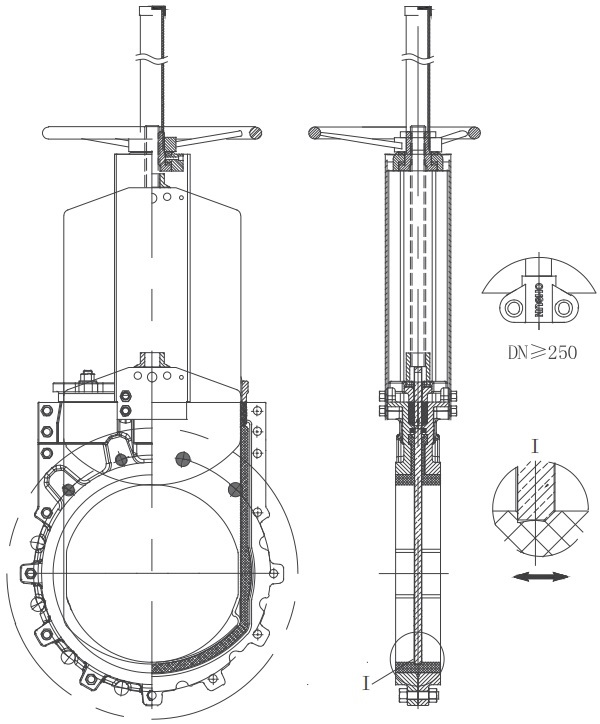

The general assembly drawing for MP-series polyurethane lined knife gate valves.

The temperature limit of PU lined knife gate valves can vary depending on the specific formulation of the polyurethane material and the application conditions. In general, polyurethane can withstand temperatures up to around 180-200°C (356-392°F) for short periods of time, but for continuous use, the temperature limit is usually lower, around 100°C(212°F). Generally, the recommended working temperature range of our MP-series knife gate valve is -30°C~100°C.