Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

In modern industrial automation, the automatic control of valves is particularly important, especially in demanding conditions and complex processes, where the operation of opening and closing valves has a direct impact on production efficiency and safety. Knife gate valves, as a commonly used shut-off valve, are widely applied in industries such as mining, chemical processing, and water treatment due to their simple structure, strong cutting force, and suitability for handling media containing particulates. To achieve automated operation, pneumatic actuators are commonly used to drive the control of knife gate valves. The double-acting pneumatic actuator is the most widely used operator for knife gate valves supplied by Metalsin.

Pneumatic-actuated knife gate valves, wafer type, ductile iron body, SS304 gate, 4″ PN16, supplied to Peru.

The working principle of a double-acting pneumatic actuator is based on the action of compressed air. The pressure from the air source pushes the piston, enabling the valve to open or close. In a double-acting actuator, the air pressure acts on both sides of the piston, allowing the actuator to both open and close the valve. Specifically:

Compared to manual or electric controls, pneumatic actuators for knife gate valves offer key benefits. They enable automated control through systems like PLCs, eliminating manual intervention, and ensure fast response, allowing quick valve operations that boost efficiency, especially in emergencies. Their high reliability comes from a simple, air-powered design, needing minimal maintenance even in harsh environments. These actuators also handle particulate and fibrous media well, making them ideal for industries such as mining, water treatment, and pulp processing.

Double-acting pneumatic actuator-operated knife gate valves for jam production line, lug type, stainless steel 316/ CF8M.

Pneumatic actuator-operated knife gate valves are widely used across various industries. In mining and metallurgy, they effectively handle media containing solid particles during ore processing and slurry transport, ensuring continuous production with fast opening and closing. In water treatment, these valves prevent blockages when processing wastewater containing solids, while pneumatic actuators enable remote automatic control, improving efficiency. In chemical and petroleum industries, knife gate valves control corrosive and particulate-laden liquids, with pneumatic actuators offering safer, more precise operation, reducing manual intervention. In pulp and paper processing, they control high-fiber slurries with precision and speed, even in high-viscosity media.

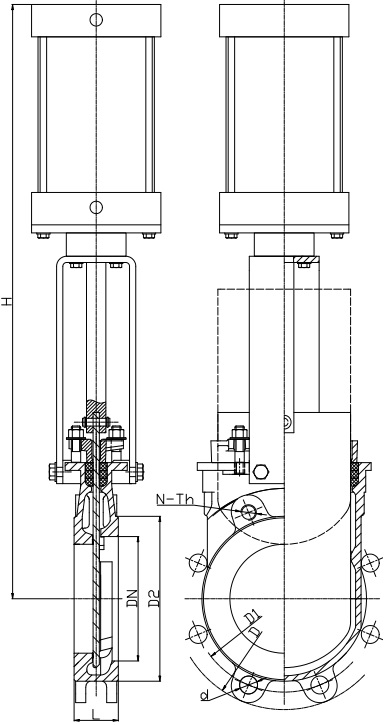

The typical G.A. drawing of pneumatic-actuated knife gate valves: wafer type, lug type, and flanged type.

The pneumatic actuator-operated knife gate valve usually adopts Metalsin‘s MB-Series knife gate valve. It uses a knife-like long steel plate as the closure member, which is lifted up and down by the pneumatic actuator to open or close the pipeline. The sealing effect of the knife gate valve is achieved through the tight fit between the gate and the rubber seat ring. The rubber seat ring is replaceable and it provides the unidirectional sealing function. There are three body patterns of the knife gate valve: wafer type, lug type, and flanged type. Depending on the specific service conditions, the valve may be furnished in ductile iron, cast steel, austenitic stainless steel, or duplex stainless steel materials. The drilling dimensions shall be in accordance with ASME B16.5 Class 150, BS 4504 PN10/PN16, EN1092-1 PN10/PN16, AS 2129 Table D/E, JIS 10K/16K.