Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

In municipal wastewater treatment plants, secondary sedimentation tanks play a crucial role in separating suspended solids and sediments from wastewater through gravity. The bottom of these tanks accumulates high-concentration sludge containing fibers, sand particles, and other debris. Controlling and discharging this abrasive and adhesive sludge requires specialized equipment. Traditional gate valves often fail in this setting due to clogging from fibrous materials, severe wear from sand abrasion, and difficulty maintaining smooth sludge discharge. These issues not only reduce system efficiency but also escalate maintenance costs.

The secondary sedimentation facility in a wastewater treatment plant in Casablanca, Morocco.

Metalsin‘s MW series knife gate valves provide an ideal solution to address these challenges. They feature the following unique designs:

Typical MW series knife gate valves: handwheel operated, non-rising stem (NRS): wafer type, lug type, double-flanged type (from left to right).

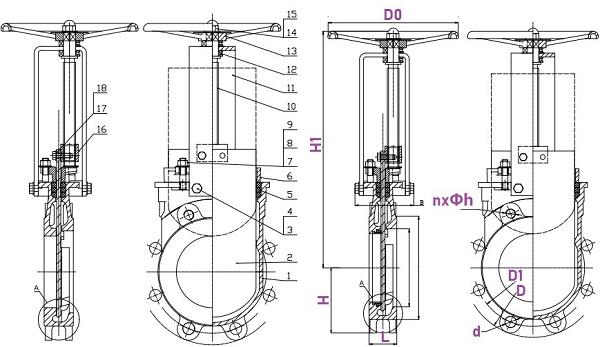

Drawing of MW-series gate valves: non-rising stem (NRS) and handwheel operated.

By supplying high performance knife gate valves specifically designed for secondary sedimentation tank pipelines, Metalsin has addressed common challenges in sludge management. Our MW-series knife gate valves ensure smooth sludge discharge, reduce downtime, and support the efficient operation of wastewater treatment systems.