Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

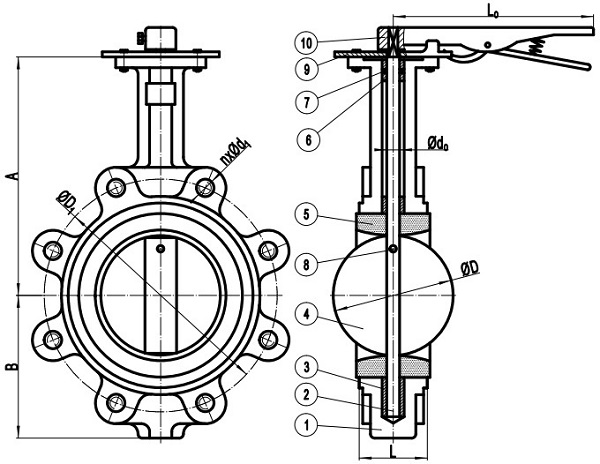

The technical drawing of MSS SP 67 lug type butterfly valve, handle lever operated, soft seated, pinned disc, with self-locking position indicator.

The MSS SP 67 lug type butterfly valve, either made of cast iron or ductile iron, has one integral flange with an identical drilling pattern to the piping flanges. Each hole is tapped from opposite direction, meeting in the center of the hole. This arrangement allows the body to be placed between two flanges. A stud is then inserted through the piping flange and threaded into the valve’s integral flange. After the stud is securely threaded into the integral flange, a nut is used to secure the entire flanged connection. MSS SP 67 lug butterfly valves are used for applications in which the risks of straight-through bolting cannot be taken (compared to wafer body design), such as with thermal expansion, when limited installation space cannot permit two integral flanges (compared to double-flanged design).

MSS SP 67 lug type butterfly valve; Body: ductile iron, disc: aluminum bronze ASTM B148 C95800, stem: stainless steel 410; Handle lever operated.

Typical design features of cast iron/ ductile iron lug type butterfly valves manufactured in accordance with MSS SP 67 include: (1)Concentric disc: the stem is attached to the disc at the exact centerline of the disc. (2)Soft seated: the seat is made of rubber or other elastomers, which fits around the entire inside diameter of the body’s flow area and is installed at one end of the body. After it is lined in place, the resilient seat protrudes slightly from the body face, allowing some final gasket compression when the valve is installed in the line. (3)Pinned disc: the disc is attached to the stem by using a taper pin, which is vibration-proof. (4)PTFE bushings: the stem is supported by close-fitting guides, which is called bushing, on both sides of the disc, which are installed in the stem bore, preventing movement of the stem and disk. (5)Positioning & locking indicator: 10 positions including fully open and fully closed are clearly marked on the indicator with self-locking device to secure sensitive flow control in throttling applications. (6)ISO 5211 mounting pad: convenient and easy connection to various operation equipment such as handle lever, gearbox, pneumatic and electric actuator, etc. (7)Body material: cast iron of ASTM A126 Class B; ductile iron of ASTM A536 Grade 60-40-18 or Grade 65-45-12.

| Item No. | Part Name | Material |

|---|---|---|

| 1 | Body | Cast Iron Ductile Iron |

| 2 | Stem | SS 304, SS316, SS 410, SS431 |

| 3 | Long Bushing | PTFE, Al-Bronze |

| 4 | Disc | SS 304, SS 316, Bronze, Al-Bronze Ductile Iron + Ni Plated |

| 5 | Seat | EPDM, NBR, Viton, PTFE |

| 6 | Short Bushing | PTFE, Al-Bronze |

| 7 | O-Ring | EPDM, NBR |

| 8 | Taper Pin | SS410 |

| 9 | Indicator | Carbon Steel |

| 10 | Handle | Cast Iron, Aluminum |

| Size | A mm | B mm | L mm |

|---|---|---|---|

| 2" | 161 | 80 | 42 |

| 2-1/2" | 175 | 89 | 45 |

| 3" | 181 | 95 | 45 |

| 4" | 200 | 114 | 51 |

| 5" | 213 | 127 | 55 |

| 6" | 226 | 139 | 55 |

| 8" | 260 | 175 | 60 |

| 10" | 292 | 203 | 67 |

| 12" | 337 | 242 | 76 |

| 14" | 368 | 267 | 76 |

| 16" | 400 | 316 | 102 |

| 18" | 422 | 334 | 114 |

| 20" | 480 | 370 | 127 |

| 22" | 533 | 433 | 151 |

| 24" | 562 | 468 | 151 |

| 26" | 540 | 484 | 172 |

| 28" | 626 | 530 | 165 |

| 32" | 602 | 675 | 190 |

| 40" | 724 | 810 | 216 |