Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

The MU-Series knife gate valves supplied by Shijiazhuang Metalsin Pipeline Tech Co., Ltd are the most widely used valve variation in various industrial and civil applications. A knife gate valve is a typical parallel gate valve that is designed to handle the flow of fluids containing solids, slurries, or other viscous & fibrous materials. The valve has a sharp edge on the bottom of the gate to shear particulates or other entrained solids as well as to separate slurries, effectively shutting off the flow. The gate is housed inside a rectangular or circular valve body, and it travels in lateral guides and is forced against the seat by wedge blocks at the bottom.

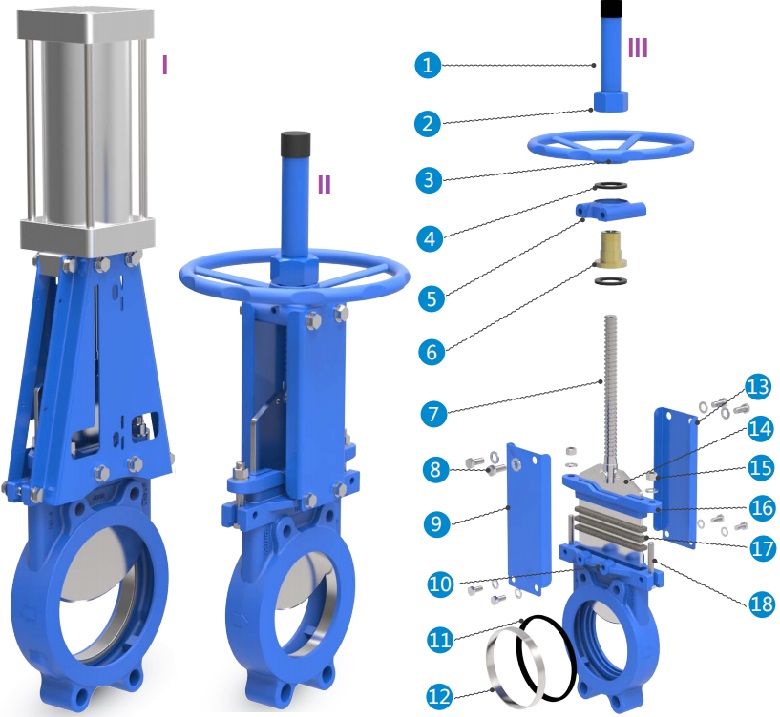

The universal knife gate valves of MU series: pneumatic actuated (I), handwheel operated (II), and the 3D exploded view (III) of the knife gate valve.

The MU-Series knife gate valves we supply are designed for miscellaneous applications in a cost-effective way: (1) Rising stem or non-rising stem can be furnished upon purchaser’s request. (2) Soft seated sealing by EPDM or PTFE will be furnished to achieve a high degree of fluid tightness. A metal retainer ring is applied to hold the EPDM or PTFE seat tightly. Both the soft seat and retainer ring are replaceable and can be conveniently maintained at site. (3) Handwheel operation is by default but other actuation methods are available upon request. (4) Dual-yoke design with improved strength. (5) Unidirectional flow design. (6) Wafer-style body makes it ideal for limited-space installation. The minimum face-to-face length also results in lighter weight of the valve. (7) The surface powder coating provides aesthetic appearance and extended life span.

There are several design standards that govern the construction and performance of knife gate valves. These standards ensure that knife gate valves are safe, reliable, and compatible with a wide range of industrial applications. Some of the most common design standards for knife gate valves include: MSS SP 81, MSS SP 135, API 609, ASME B16.34, API 598, ISO 5208, GB/T 12237, JB/T 8691, BS EN 593, AS 4794, JIS B2063. It’s worth noting that some of these standards, such as the BS EN 593 and AS 4794, cover butterfly valves in general rather than specifically knife gate valves. However, many of the principles and requirements outlined in these standards are also applicable to knife gate valves.

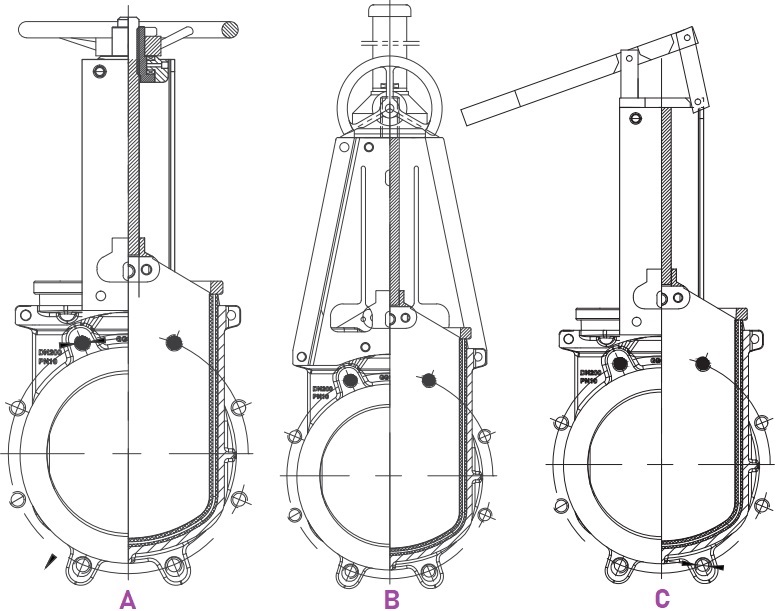

Various operating methods for knife gate valves: A-Handwheel; B-Gearbox; C-Lever.

The MU-Series knife gate valves are available in a wide range of sizes and working pressures, depending on their intended application. Here are some general guidelines for selecting the appropriate size for a rated working pressure: (1)DN50-DN100, 16 bar; (2)DN125-DN200, 14 bar; (3)DN250-DN300, 12 Bar; (4)DN350-DN400, 10 bar; (5)DN450-DN550, 8 bar; (6)DN600-DN650, 5 bar; (7)DN700-DN750, 4 bar; (8)DN800-DN900, 3 bar; (9)DN1000-DN1400, 2 bar.

The selection of materials for each part of the knife gate valve depends on several factors, including the intended application, the process media being handled, and the operating conditions(temperature, pressure, etc). Here are some general guidelines for material selection for each part of the valve as illustrated by the 3D exploded view (picture-III above).

| Item No. | Part Name | Material |

|---|---|---|

| 1 | Handle Cover | Carbon Steel |

| 2 | Handle Nut | SS201 |

| 3 | Handwheel | GGG 40 |

| 4 | Bearing | ZChSnSb10-6 |

| 5 | Yoke Connector | GGG40 |

| 6 | Stem Nut | Brass |

| 7 | Stem | 2Cr13 SS304 SS316 |

| 8 | Bolt | SS201 SS304 |

| 9 | Yoke | Carbon Steel |

| 10 | Body | GGG 40 WCB CF8/ CF8M CF3/ CF3M |

| 11 | Seat | EPDM/NBR PTFE/Metal |

| 12 | Seat Retainer | A105 SS304 SS316 |

| 13 | Yoke | Carbon Steel |

| 14 | Disc | SS304/SS316 Duplex 2205 A182 Gr. F55 |

| 15 | Nut | SS201/SS304 |

| 16 | Packing Gland | WCB/CF8 |

| 17 | Packing | PTFE Aramid Rubber Graphite |

| 18 | Body Bolt | SS304 |

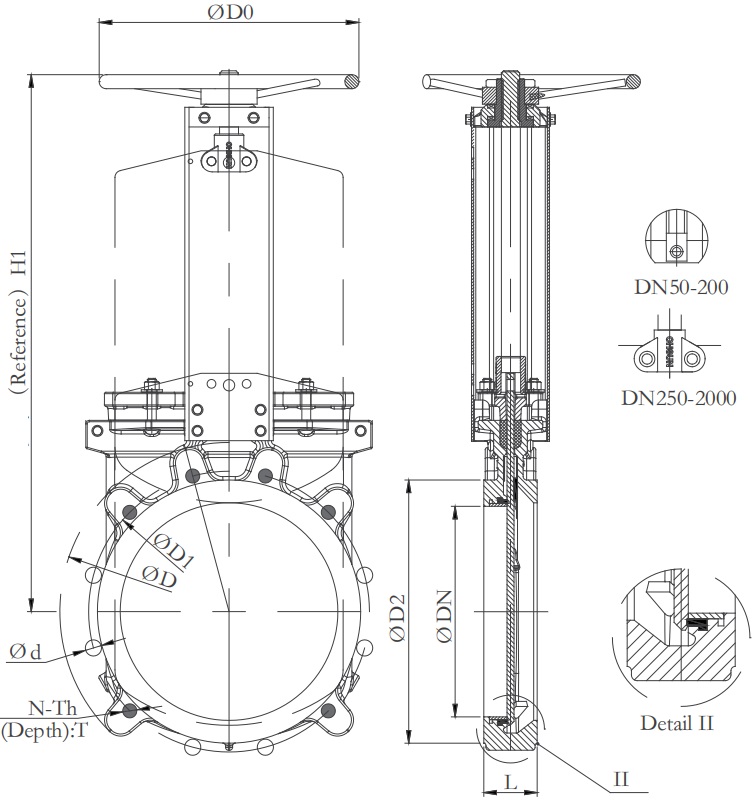

The G.A. drawing for MU series knife gate valves.

| Size | ΦD0 | H1 | L |

|---|---|---|---|

| 2" | 180 | 260 | 48 |

| 2-1/2" | 200 | 292 | 48 |

| 3" | 200 | 320 | 51 |

| 4" | 240 | 358 | 51 |

| 5" | 260 | 395 | 57 |

| 6" | 280 | 450 | 57 |

| 8" | 300 | 532 | 70 |

| 10" | 320 | 670 | 70 |

| 12" | 350 | 758 | 76 |

| 14" | 400 | 857 | 76 |

| 16" | 450 | 946 | 89 |

| 18" | 500 | 1023 | 89 |

Basic structural dimensions of the MU-series knife gate valves are provided. The drilling dimensions of the valve shall be in compliance to a set of international pipe flange standards including Class 150 of ASME B16.5, PN10 & PN16 of EN1092-1, BS 4504, DIN, 10K & 16K of JIS B2220, Table D & Table E of BS 10.

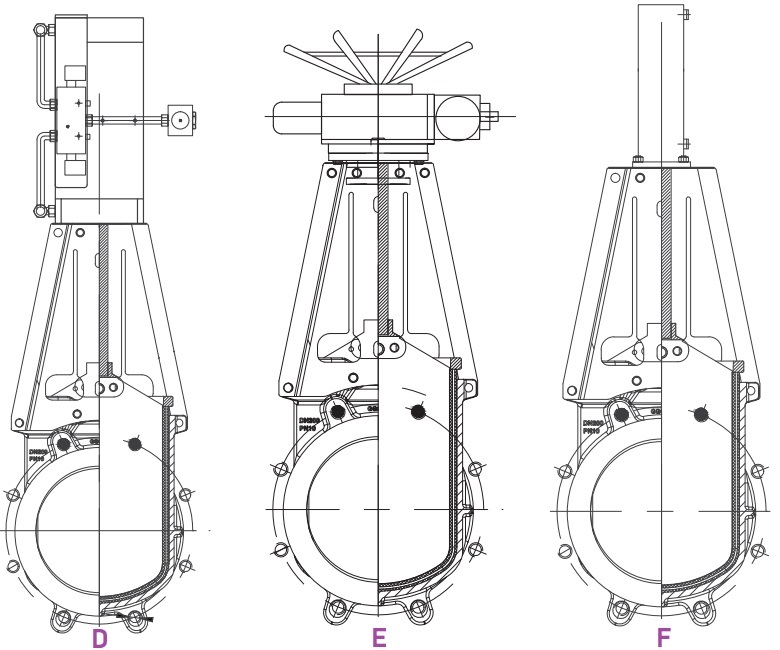

Various actuation methods for knife gate valves: D – pneumatic actuator; E – electrical actuator; F – hydraulic actuator.

MU-series knife gate valves are commonly used in applications where a full-port flow path is required, and where the media being handled contains solids, slurries, or viscous fluids. Here are some common applications and services of knife gate valves: mining, pulp and paper, chemical processing, power generation, food and beverage, urban water supply and wastewater treatment, oil and gas, pharmaceuticals, steel production (metallurgy industry), marine and offshore, HVAC systems, and agriculture. The versatility and reliability of these valves make them an excellent choice for many different industries and services.