Product Categories

- Products (61)

Lap joint stub ends made of Grade 2 titanium of ASTM B363, seamless & long pattern, ASME B16.9 2" & 3" SCH40.

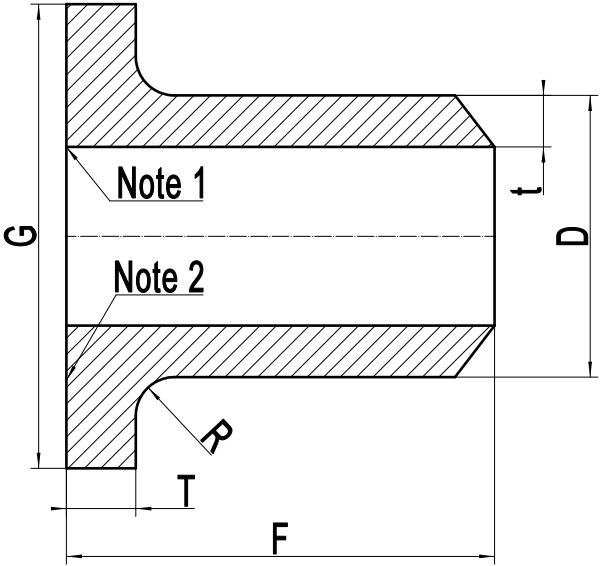

The Grade 2 titanium stub end is a butt-welding fitting made from commercially pure titanium grade 2 (UNS R50400). It consists of two sections: the straight pipe length and the lap, as shown in Figure-1. It is usually used with a lap-joint flange or backing ring to form a bolted assembly. The straight pipe length shall be furnished with the same outside diameter and wall thickness as that of the piping. The lap thickness P shall not be less than nominal pipe wall thickness t. The diameter of lap G conforms to standard machined facings of the RF flange. The fillet between the lap and the straight pipe length shall be furnished to avoid stress concentration. The radius of fillet, R, conforms to the radius established for the lap-joint flange or backing ring.

Figure-1: the typical drawing of titanium Gr.2 stub end. D: outside diameter of piping, t: wall thickness of piping, G: diameter of lap, R: radius of fillet, T: thickness of lap, F: length of stub end. Note 1: the internal square corner shall be furnished; Note 2: the gasket face finish shall be in accordance with ASME B16.5 for raised-face flanges.

The Grade 2 titanium stub end is also called “pressed collar” or “lapped pipe end”. They can be made in accordance with a variety of international standards such as MSS SP 43, ASME B16.9, EN 1092-1 Type 36 & 37, MSS SP 43, DIN 2642, HG 25099, GB/T 12459, etc. They are available in long pattern or short pattern, in nominal wall thickness of SCH 5, SCH 5S, SCH 10, SCH 10S, SCH 20, SCH 20S, SCH 40, SCH 40S, and STD. The Grade 2 titanium stub end & carbon steel lap-joint flange assembly not only provides economic solution for excellent corrosion resistance, but also facilitates frequent dismantling for inspection or routine maintenance in piping systems.

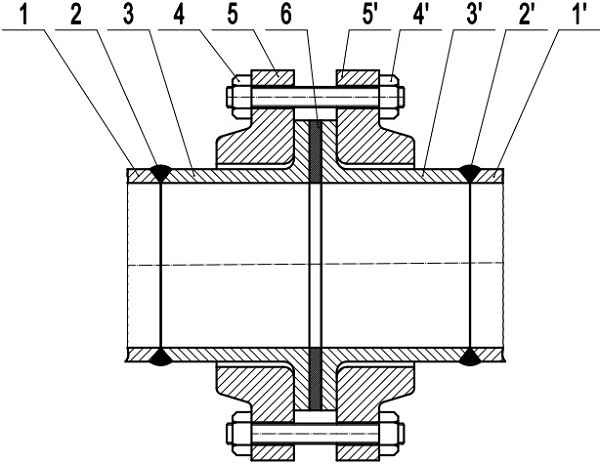

Figure-2: the Grade 2 titanium stub end and carbon steel lap-joint flange assembly used in piping system.

As illustrated in Figure-2, 1 & 1′ are the titanium piping through which corrosive fluid flows. They are attached to Grade 2 titanium stub ends 3 & 3′ respectively by the butt welding process. The carbon steel lap-joint flanges 5 & 5′ slip over the straight pipe length of the stub end and sit onto the back surface of the lap. The two backing flanges are bolted up by the fasteners 4 & 4′, compressing the laps against the flat gasket 6 to achieve tight sealing. Only the titanium stub ends and the piping are in contact with the fluid medium.

The commercially pure titanium Grade 2 is a highly reactive metal. It has an extremely high affinity for oxygen and thus forms a very stable and highly adherent protective oxide film on its surface. This oxide film, which forms spontaneously and instantly when fresh metal surfaces are exposed to air and/or moisture, provides the excellent corrosion resistance of titanium. Besides, Grade 2 titanium is the “workhorse” for industrial applications, having a guaranteed minimum yield strength of 275 MPa [40 ksi] and good ductility and formability, as well as good impact properties at low temperatures.

A Grade 2 titanium stub end made in accordance with ASTM B363, 4″ SCH 40S short pattern, supplied to Pennsylvania, USA.

The Grade 2 titanium has good resistance to mildly reducing and highly oxidizing environments in which protective TiO2 and Ti2O3 films form spontaneously and remain stable. On the other hand, uninhibited, strongly reducing acidic environments may attack titanium, particularly as temperature increases. It may be subject to localized attack in tight crevices exposed to hot (>70°C, or 160°F) chloride, bromide, iodide, fluoride, or sulfate-containing solutions. In general, Grade 2 titanium is resistant to attack by seawater, moist chlorine, moist metallic chlorides, chlorite and hypochlorite solutions, nitric and chromic acids, organic acids, sulfides, and many industrial gaseous environments.

Grade 2 titanium stub ends may be furnished in seamless type (for sizes 4″ and smaller) or welded type (for sizes 5″ and larger). The welded stub end is made by welding a pre-fabricated titanium ring onto the straight pipe length. After TIG welding, proper grinding and X-ray inspection shall be performed. The stub end made by a seamless process is more complicated: (1) The titanium grade 2 seamless pipe shall be cut into pieces of calculated length. (2) The cut piece is then fed through a tubular die. Part of the straight length is seated within the die, while the other part is stretched out of the die. (3) Use a torch to heat up the stretch-out section of the titanium pipe to a temperature between 500~600°C. (4) Flare the stretch-out section at the high temperature by multiple lapping and pressing operations till it is flattened completely. (5) The formed titanium stub end shall be stress-relieved, pickled and cleaned.

Due to the much lower modulus of elasticity of titanium, which is only half of that of austenitic stainless steel or carbon steel, the cold forming of a Grade 2 titanium stub end is very difficult. Besides, the anisotropic crystal structure of α-titanium makes it susceptible to cracking during cold working. This is why torch-heating is necessary in the seamless process. The stress-relieving treatment shall be conducted after the forming process. The Ti Gr.2 stub end shall be held at a minimum temperature of 1100°F for not less than 0.5 hour per inch of thickness.