Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

Globe valves are valves in which the shut-off piece moves along the center line of the seat. Globe valve is the most widely used type of valve, this type of valve is very suitable for cutting or adjusting and throttling, but also suitable for medium and low pressure.

A typical flanged plunger globe valve

Globe valves can be designed and manufactured in accordance with a variety of major standards and Codes including JB/T 7746 (Compact steel valves), JIS B 2071 (Steel valves), BS 5352 (Specification for Steel wedge gate, globe and check valves 50 mm and smaller for the petroleum, petrochemical and allied industries), ASME B16.34 (Valves — Flanged, Threaded, and Welding End), BS 1873 (Specification for steel globe and globe stop and check valves -flanged and butt-welding ends for the petroleum, petrochemical and allied industries), MSS-SP-42 (Class 150 Corrosion Resistant Gate, Globe, Angle, and Check Valves with Flanged and Butt Weld Ends), GB/T 12235 (Steel globe valves and lift check valve for petroleum, petrochemical and allied industried), MSS-SP-85 (Gray Iron Globe & Angle Valves Flanged and Threaded Ends), BS 5154 (Specification for copper alloy globe, globe stop and check, check and gate valves), etc.

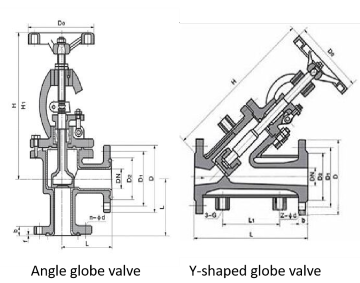

Globe valves can be divided into three types according to their channel direction: angle globe valve, plunger globe valve and Y-shaped globe valve. Angle globe valve: the flow changes direction only once, so that the pressure drop through the valve is smaller than in a conventional globe valve. Most of the angle globe valve is forging, suitable for small diameter and high pressure. Plunger globe valve: this type of globe valve is mainly used for “on” or “off”, while use a special form of plunger or special ring, can also be used for flow regulation. Y-shaped globe valve: this type of valve body flow path and the main flow path into a diagonal line, so the flow state of the damage than the conventional globe valve is smaller, so the pressure loss through the valve is also reduced accordingly, mostly used to contain solid particles or viscosity of the fluid.

G.A drawings for Angle globe valve & Y-shaped globe valve

Globe valves can also be classified according to different positions of threads on the stem of globe valves: upper threaded stem globe valve and lower threaded stem globe valve. The globe valve stem threads are outside the valve body is the upper threaded stem globe valve. Its advantage is that the valve stem is not subject to the erosion of the medium, easy to lubricate, this kind of structure is more common. Lower threaded stem globe valve, this type of the thread of the globe valve stem is in the valve body. Stem threads of this construction are in direct contact with the medium and are subject to erosion and are not lubricated. This kind of structure is used for small diameter and low temperature.

Globe valves classification according to the different seal material: soft seated globe valve and hard seated globe valve. Soft seated globe valve, which the sealing pair on both sides of the metal material, the other side is elastic non-metal material, known as the “soft seal”. Sealing material using soft material such as: plastic, polytetrafluoroethylene, nylon, etc., soft seated globe valves basically use PTFE gasket, there are also high temperature gasket PPL. This kind of seal sealing performance is better, but not resistant to high temperature, easy to wear, mechanical poor. Hard seated globe valve refers to the sealing material is made of metal: copper seal, stainless steel, nickel base alloy. This kind of globe valve sealing performance is poor, but high temperature, wear resistance, good mechanical performance.