Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

Gate valve is a linear-motion valve characterized by a body with a longer face-to-face that acommodates flow passages sufficiently long enough to ensure smooth flow through the valve without any sharp turns.

Gate valve with the gate as opening and closing parts, the movement direction of the gate is perpendicular to the flow direction, gate valve can only be fully open and closed, can not be adjusted and throttle. Gate valves are sealed by contact between the seat and the gate, usually by surfacing metal to increase wear resistance, such as surfacing 1Cr13, STL6, stainless steel, etc.

API 600 Flanged Gate Valve

Gate valves can be designed and manufactured in the light of many major standards and codes including JB/T 7746 (Reduced diameter forged steel valve), API 602 (Gate, Globe, and Check valves for sizes DN100 and smaller for the petroleum and natural gas industries), API 6D (Specification for Pipelineand Piping Valves), GB/T 12234 (Bolted bonnet steel gate valves for petroleum and natural gas industries), API 600, ISO 10434 (Bolted bonnet steel gate valves for the petroleum, petrochemical and allied industries), ASME B16.34 (Valves—Flanged, Threaded, and Welding End), MSS-SP-81 (Stainless-Steel or Stainless-Steel-Lined, Bonnetless, Knife Gate Valves with Flanged Ends), BS 5157 (Specification for Steel gate parallel slide valves), etc.

Gate valves can be classified in many ways. One typical way to classify valves is according to the structure of gate. Parallel gate valve, has two sealing faces, the sealing faces are parallel to the vertical center line. Wedge gate valve, the two sealing surfaces are wedged, the sealing surface is at an angle to the vertical center line.

Gate valves classification according to the material they are made from: cast steel gate valve, cast iron gate valve and forged steel gate valve.

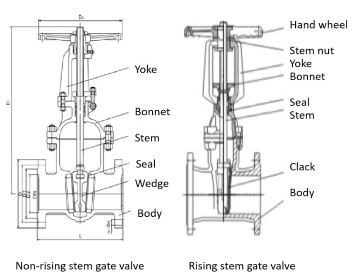

Non-rising stem gate valve & Rising stem gate valve

Gate valves can also be classified according to the different stucture of the valve stem. Rising stem gate valve, which the valve stem nut is on the bonnet or bracket, the valve stem can be lifted and lowered by rotating the valve stem nut when the gate is opened and closed. This kind of structure is advantageous to the lubrication of the valve stem, and the opening and closing degree is obvious, so it is widely used. Non-rising stem gate valve: the stem nut is in the valve body and directly contacts with the medium. It is realized by rotating the valve stem when the gate is opened and closed.