Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

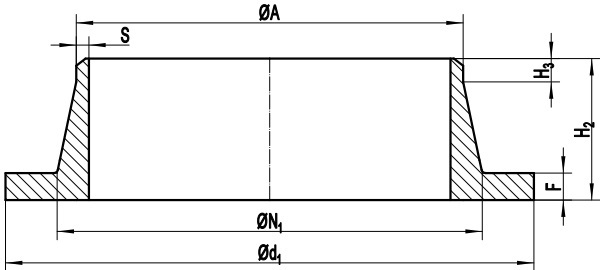

Figure-1: the technical drawing of the EN 1092-1 Type 34 weld neck collar. Φd1: outside diameter of flange/ collar facing; ΦN1: neck dimension at root; ΦA: outside diameter of neck (pipe o.d.); S: wall thickness of piping; H3:straight length of hub; H2: total length of collar; F: collar thickness. W: weight/ mass of collar.

The EN 1092-1 Type 34 weld neck collar resembles a weld neck flange. It consists of a tapered hub with a short straight length plus a flared end. The taper of the hub generally has an angle not exceeding 7° on the outside surface for forging purpose. The tapered section of the hub provides an enhancement to the collar strength. Its outside diameter (ΦN1) at the neck root is larger than common straight collars. The straight-length section of the hub is furnished to facilitate the attachment to the piping by a butt welding process. The collar thickness, F, is the same as that of Type 32 plate collar. Usually, Type 34 weld neck collars shall be manufactured by a forging process. They are available in sizes DN10~DN600 for PN 10, DN10~DN600 for PN 16, DN10~DN500 for PN 25, and DN10~DN600 for PN 40, respectively.

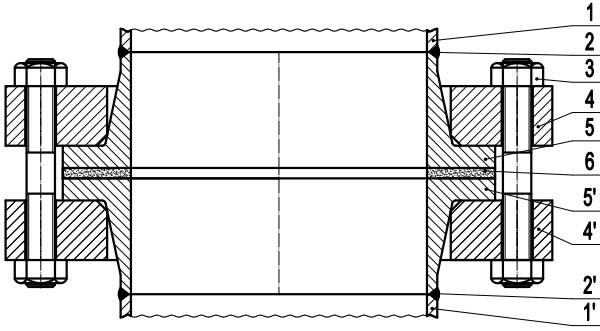

Figure-2: the illustration of a flanged joint in piping by using the EN 1092-1 Type 34 + Type 04 assembly. 1 & 1′: piping; 2 & 2′: butt welding to attach the pipe to Type 34 weld-neck collar; 4 & 4′: Type 04 loose plate flange; 5 & 5′: Type 34 weld-neck collar; 3: bolting; 6: gasket.

EN 1092-1 Type 34 weld-neck collar shall always work together with a Type 04 loose plate flange. The Type 04 flange has enlarged bore diameter to accommodate the relatively larger neck diameter (ΦN1) of the Type 34 collar. As illustrated in Figure-2, the Type 34 collar is attached to the piping by butt welding. The Type 04 loose plate flange slips over the hub of the wed-neck collar and is seated onto the shoulder of the flared end. Bolting is tightened to compress the gasket against the facings of two Type 34 collars to achieve fluid-tight sealing.

| EN 1092-1 Loose Plate Flanges & Collars | |||

|---|---|---|---|

| Type 02 | Type 04 | Type 32 | Type 33 |

| Type 34 | Type 35 | Type 36 | Type 37 |

| DN | d1 mm | N1 mm | A mm | S mm |

|---|---|---|---|---|

| 10 | 40 | 28 | 17.2 | 1.8 |

| 15 | 45 | 32 | 21.3 | 2.0 |

| 20 | 58 | 40 | 26.9 | 2.3 |

| 25 | 68 | 46 | 33.7 | 2.6 |

| 32 | 78 | 56 | 42.4 | 2.6 |

| 40 | 88 | 64 | 48.3 | 2.6 |

| 50 | 102 | 74 | 60.3 | 2.9 |

| 65 | 122 | 92 | 76.1 | 2.9 |

| 80 | 138 | 105 | 88.9 | 3.2 |

| 100 | 158 | 131 | 114.3 | 3.6 |

| 125 | 188 | 156 | 139.7 | 4.0 |

| 150 | 212 | 184 | 168.3 | 4.5 |

| 200 | 268 | 234 | 219.1 | 6.3 |

| 250 | 320 | 292 | 273.0 | 6.3 |

| 300 | 370 | 342 | 323.9 | 7.1 |

| 350 | 430 | 385 | 355.6 | 7.1 |

| 400 | 482 | 440 | 406.4 | 7.1 |

| 450 | 532 | 488 | 457.0 | 7.1 |

| 500 | 585 | 542 | 508.0 | 7.1 |

| 600 | 685 | 642 | 610.0 | 8.0 |

| DN | H2 mm | H3 mm | F mm | W kg |

|---|---|---|---|---|

| 10 | 35 | 6 | 12 | 0.148 |

| 15 | 38 | 6 | 12 | 0.189 |

| 20 | 40 | 6 | 14 | 0.340 |

| 25 | 40 | 6 | 14 | 0.444 |

| 32 | 42 | 6 | 14 | 0.572 |

| 40 | 45 | 7 | 14 | 0.734 |

| 50 | 45 | 8 | 16 | 0.974 |

| 65 | 45 | 10 | 16 | 1.29 |

| 80 | 50 | 10 | 16 | 1.67 |

| 100 | 52 | 12 | 18 | 2.12 |

| 125 | 55 | 12 | 18 | 2.88 |

| 150 | 55 | 12 | 20 | 3.46 |

| 200 | 62 | 16 | 20 | 5.49 |

| 250 | 68 | 16 | 22 | 7.53 |

| 300 | 68 | 16 | 22 | 9.11 |

| 350 | 68 | 16 | 22 | 14.1 |

| 400 | 72 | 16 | 24 | 17.8 |

| 450 | 72 | 16 | 24 | 19.6 |

| 500 | 75 | 16 | 26 | 23.7 |

| 600 | 82 | 18 | 26 | 28.9 |

| DN | d1 mm | N1 mm | A mm | S mm |

|---|---|---|---|---|

| 10 | 40 | 28 | 17.2 | 1.8 |

| 15 | 45 | 32 | 21.3 | 2.0 |

| 20 | 58 | 40 | 26.9 | 2.3 |

| 25 | 68 | 46 | 33.7 | 2.6 |

| 32 | 78 | 56 | 42.4 | 2.6 |

| 40 | 88 | 64 | 48.3 | 2.6 |

| 50 | 102 | 74 | 60.3 | 2.9 |

| 65 | 122 | 92 | 76.1 | 2.9 |

| 80 | 138 | 105 | 88.9 | 3.2 |

| 100 | 158 | 131 | 114.3 | 3.6 |

| 125 | 188 | 156 | 139.7 | 4.0 |

| 150 | 212 | 184 | 168.3 | 4.5 |

| 200 | 268 | 235 | 219.1 | 6.3 |

| 250 | 320 | 292 | 273.0 | 6.3 |

| 300 | 378 | 344 | 323.9 | 7.1 |

| 350 | 438 | 390 | 355.6 | 8.0 |

| 400 | 490 | 445 | 406.4 | 8.0 |

| 450 | 550 | 490 | 457.0 | 8.0 |

| 500 | 610 | 548 | 508.0 | 8.0 |

| 600 | 725 | 670 | 610.0 | 8.8 |

| DN | H2 mm | H3 mm | F mm | W kg |

|---|---|---|---|---|

| 10 | 35 | 6 | 12 | 0.148 |

| 15 | 38 | 6 | 12 | 0.189 |

| 20 | 40 | 6 | 14 | 0.340 |

| 25 | 40 | 6 | 14 | 0.444 |

| 32 | 42 | 6 | 14 | 0.572 |

| 40 | 45 | 7 | 14 | 0.734 |

| 50 | 45 | 8 | 16 | 0.974 |

| 65 | 45 | 10 | 16 | 1.29 |

| 80 | 50 | 10 | 16 | 1.67 |

| 100 | 52 | 12 | 18 | 2.12 |

| 125 | 55 | 12 | 18 | 2.88 |

| 150 | 55 | 12 | 20 | 3.46 |

| 200 | 62 | 16 | 20 | 5.55 |

| 250 | 70 | 16 | 22 | 7.71 |

| 300 | 78 | 16 | 24 | 11.4 |

| 350 | 82 | 16 | 26 | 19.2 |

| 400 | 85 | 16 | 28 | 23.7 |

| 450 | 83 | 18 | 30 | 28.2 |

| 500 | 84 | 18 | 32 | 35.5 |

| 600 | 88 | 18 | 32 | 47.9 |

| DN | d1 mm | N1 mm | A mm | S mm |

|---|---|---|---|---|

| 10 | 40 | 28 | 17.2 | 1.8 |

| 15 | 45 | 32 | 21.3 | 2.0 |

| 20 | 58 | 40 | 26.9 | 2.3 |

| 25 | 68 | 46 | 33.7 | 2.6 |

| 32 | 78 | 56 | 42.4 | 2.6 |

| 40 | 88 | 64 | 48.3 | 2.6 |

| 50 | 102 | 75 | 60.3 | 2.9 |

| 65 | 122 | 90 | 76.1 | 2.9 |

| 80 | 138 | 105 | 88.9 | 3.2 |

| 100 | 162 | 134 | 114.3 | 3.6 |

| 125 | 188 | 162 | 139.7 | 4.0 |

| 150 | 218 | 192 | 168.3 | 4.5 |

| 200 | 278 | 244 | 219.1 | 6.3 |

| 250 | 335 | 298 | 273.0 | 7.1 |

| 300 | 395 | 352 | 323.9 | 8.0 |

| 350 | 450 | 398 | 355.6 | 8.0 |

| 400 | 505 | 452 | 406.4 | 8.8 |

| 450 | 555 | 500 | 457.0 | 8.8 |

| 500 | 615 | 558 | 508.0 | 10.0 |

| DN | H2 mm | H3 mm | F mm | W kg |

|---|---|---|---|---|

| 10 | 35 | 6 | 12 | 0.148 |

| 15 | 38 | 6 | 12 | 0.189 |

| 20 | 40 | 6 | 14 | 0.340 |

| 25 | 40 | 6 | 14 | 0.444 |

| 32 | 42 | 6 | 14 | 0.572 |

| 40 | 45 | 7 | 14 | 0.734 |

| 50 | 48 | 8 | 16 | 1.02 |

| 65 | 52 | 10 | 16 | 1.36 |

| 80 | 58 | 12 | 18 | 1.90 |

| 100 | 65 | 12 | 20 | 2.77 |

| 125 | 68 | 12 | 22 | 3.78 |

| 150 | 75 | 12 | 24 | 5.25 |

| 200 | 80 | 16 | 26 | 9.07 |

| 250 | 88 | 18 | 26 | 12.7 |

| 300 | 92 | 18 | 28 | 18.0 |

| 350 | 100 | 20 | 32 | 27.8 |

| 400 | 110 | 20 | 34 | 36.3 |

| 450 | 110 | 20 | 36 | 40.9 |

| 500 | 125 | 20 | 38 | 55.7 |

| DN | d1 mm | N1 mm | A mm | S mm |

|---|---|---|---|---|

| 10 | 40 | 28 | 17.2 | 1.8 |

| 15 | 45 | 32 | 21.3 | 2.0 |

| 20 | 58 | 40 | 26.9 | 2.3 |

| 25 | 68 | 46 | 33.7 | 2.6 |

| 32 | 78 | 56 | 42.4 | 2.6 |

| 40 | 88 | 64 | 48.3 | 2.6 |

| 50 | 102 | 75 | 60.3 | 2.9 |

| 65 | 122 | 90 | 76.1 | 2.9 |

| 80 | 138 | 105 | 88.9 | 3.2 |

| 100 | 162 | 134 | 114.3 | 3.6 |

| 125 | 188 | 162 | 139.7 | 4.0 |

| 150 | 218 | 192 | 168.3 | 4.5 |

| 200 | 285 | 244 | 219.1 | 6.3 |

| 250 | 345 | 306 | 273.0 | 7.1 |

| 300 | 410 | 362 | 323.9 | 8.0 |

| 350 | 465 | 408 | 355.6 | 8.8 |

| 400 | 535 | 462 | 406.4 | 11.0 |

| 450 | 560 | 500 | 457.0 | 12.5 |

| 500 | 615 | 562 | 508.0 | 14.2 |

| 600 | 735 | 666 | 610.0 | 16.0 |

| DN | H2 mm | H3 mm | F mm | W kg |

|---|---|---|---|---|

| 10 | 35 | 6 | 12 | 0.148 |

| 15 | 38 | 6 | 12 | 0.189 |

| 20 | 40 | 6 | 14 | 0.340 |

| 25 | 40 | 6 | 14 | 0.444 |

| 32 | 42 | 6 | 14 | 0.572 |

| 40 | 45 | 7 | 14 | 0.734 |

| 50 | 48 | 8 | 16 | 1.02 |

| 65 | 52 | 10 | 16 | 1.36 |

| 80 | 58 | 12 | 18 | 1.90 |

| 100 | 65 | 12 | 20 | 2.77 |

| 125 | 68 | 12 | 22 | 3.78 |

| 150 | 75 | 12 | 24 | 5.25 |

| 200 | 88 | 16 | 28 | 10.2 |

| 250 | 105 | 18 | 30 | 16.4 |

| 300 | 115 | 18 | 34 | 25.4 |

| 350 | 125 | 20 | 36 | 37.8 |

| 400 | 135 | 20 | 42 | 56.4 |

| 450 | 135 | 20 | 46 | 56.4 |

| 500 | 140 | 20 | 50 | 72.9 |

| 600 | 150 | 20 | 54 | 106 |