Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

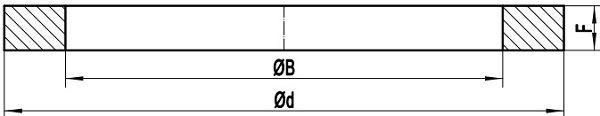

Figure-1: technical drawing for EN 1092-1 Type 32 weld-on plate collar. B: bore diameter; d: outside diameter; F: collar thickness.

The EN 1092-1 Type 32 weld on plate collar is a typical flat metallic ring available in PN 6, PN 10, PN 16, PN 25 and PN 40. The bore diameter B is exactly the same as that of the Type 01 flange but a bit smaller than that of the mating Type 02 loose plate flange. The outside diameter d is equal to that of the raised face of the mating flange. There is no need for the drilling of bolt holes. Type 32 of EN 1092-1 is called “collar” not “flange” since it works as a lapped/ flared end, functioning as a raised face of a flange as illustrated in Figure-2. The collar thickness F is comparatively smaller than the thickness of the mating flange.

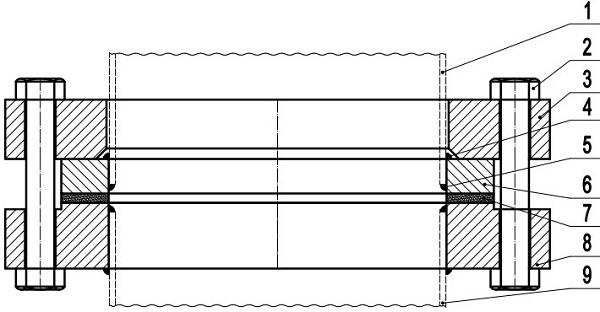

Figure-2: illustration of a bolted flange joint incorporating the EN 1092-1 “Type 02 + Type 32” assembly. 1 & 9: pipes; 2: bolting; 3: Type 02 loose plate flange; 4 & 5: fillet welds; 6: Type 32 weld-on plate collar; 7: gasket; 8: Type 01 plate flange with RF.

EN 1092-1 Type 32 weld-on plate collar shall always be used with a Type 02 loose plate flange. As shown in Figure-2, the Type 02 flange serves as a backing ring to hold the Type 32 collar. The piping slips through Type 02 flange to the end of the Type 32 plate collar. Two fillet welds at the illustrated positions are required to ensure that only the plate collar can be in contact with the fluid. A flat or spiral wound gasket shall be put in between the Type 32 plate collar and the raised face of the mating Type 01 flange. The surface finish of the plate collar adjacent to the gasket shall be furnished by a turning process with 3.2 μm ≤ Ra ≤ 12.5 μm and 12.5 μm ≤ Rz ≤ 50.0 μm.

| EN 1092-1 Loose Plate Flanges & Collars | |||

|---|---|---|---|

| Type 02 | Type 04 | Type 32 | Type 33 |

| Type 34 | Type 35 | Type 36 | Type 37 |

| DN | d mm | B mm | F mm | Mass kg |

|---|---|---|---|---|

| 10 | 35 | 18.0 | 10 | 0.056 |

| 15 | 40 | 22.0 | 10 | 0.069 |

| 20 | 50 | 27.5 | 10 | 0.108 |

| 25 | 60 | 34.5 | 10 | 0.149 |

| 32 | 70 | 43.5 | 10 | 0.185 |

| 40 | 80 | 49.5 | 10 | 0.244 |

| 50 | 90 | 61.5 | 12 | 0.319 |

| 65 | 110 | 77.5 | 12 | 0.451 |

| 80 | 128 | 90.5 | 12 | 0.606 |

| 100 | 148 | 116.0 | 14 | 0.729 |

| 125 | 178 | 141.5 | 14 | 1.00 |

| 150 | 202 | 170.5 | 14 | 1.01 |

| 200 | 258 | 221.5 | 16 | 1.73 |

| 250 | 312 | 276.5 | 18 | 2.32 |

| 300 | 365 | 327.5 | 18 | 2.88 |

| 350 | 415 | 359.5 | 18 | 4.77 |

| 400 | 465 | 411.0 | 20 | 5.83 |

| 450 | 520 | 462.0 | 20 | 7.02 |

| 500 | 570 | 513.5 | 22 | 8.30 |

| 600 | 670 | 616.5 | 22 | 9.34 |

| DN | d mm | B mm | F mm | Mass kg |

|---|---|---|---|---|

| 10 | 40 | 18.0 | 12 | 0.094 |

| 15 | 45 | 22.0 | 12 | 0.114 |

| 20 | 58 | 27.5 | 14 | 0.225 |

| 25 | 68 | 34.5 | 14 | 0.296 |

| 32 | 78 | 43.5 | 14 | 0.362 |

| 40 | 88 | 49.5 | 14 | 0.457 |

| 50 | 102 | 61.5 | 16 | 0.653 |

| 65 | 122 | 77.5 | 16 | 0.876 |

| 80 | 138 | 90.5 | 16 | 1.07 |

| 100 | 158 | 116.0 | 18 | 1.28 |

| 125 | 188 | 141.5 | 18 | 1.70 |

| 150 | 212 | 170.5 | 20 | 1.96 |

| 200 | 268 | 221.5 | 20 | 2.81 |

| 250 | 320 | 276.5 | 22 | 3.52 |

| 300 | 370 | 327.5 | 22 | 4.02 |

| 350 | 430 | 359.5 | 22 | 7.55 |

| 400 | 482 | 411.0 | 24 | 9.38 |

| 450 | 532 | 462.0 | 24 | 10.3 |

| 500 | 585 | 513.5 | 26 | 12.6 |

| 600 | 685 | 616.5 | 26 | 14.3 |

| DN | d mm | B mm | F mm | Mass kg |

|---|---|---|---|---|

| 10 | 40 | 18.0 | 12 | 0.094 |

| 15 | 45 | 22.0 | 12 | 0.114 |

| 20 | 58 | 27.5 | 14 | 0.225 |

| 25 | 68 | 34.5 | 14 | 0.296 |

| 32 | 78 | 43.5 | 14 | 0.362 |

| 40 | 88 | 49.5 | 14 | 0.457 |

| 50 | 102 | 61.5 | 16 | 0.653 |

| 65 | 122 | 77.5 | 16 | 0.876 |

| 80 | 138 | 90.5 | 16 | 1.07 |

| 100 | 158 | 116.0 | 18 | 1.28 |

| 125 | 188 | 141.5 | 18 | 1.70 |

| 150 | 212 | 170.5 | 20 | 1.96 |

| 200 | 268 | 221.5 | 20 | 2.81 |

| 250 | 320 | 276.5 | 22 | 3.52 |

| 300 | 378 | 327.5 | 24 | 5.27 |

| 350 | 438 | 359.5 | 26 | 10.1 |

| 400 | 490 | 411.0 | 28 | 12.3 |

| 450 | 550 | 462.0 | 30 | 16.5 |

| 500 | 610 | 513.5 | 32 | 21.4 |

| 600 | 725 | 616.5 | 32 | 28.7 |

| DN | d mm | B mm | F mm | Mass kg |

|---|---|---|---|---|

| 10 | 40 | 18.0 | 12 | 0.094 |

| 15 | 45 | 22.0 | 12 | 0.114 |

| 20 | 58 | 27.5 | 14 | 0.225 |

| 25 | 68 | 34.5 | 14 | 0.296 |

| 32 | 78 | 43.5 | 14 | 0.362 |

| 40 | 88 | 49.5 | 14 | 0.457 |

| 50 | 102 | 61.5 | 16 | 0.653 |

| 65 | 122 | 77.5 | 16 | 0.876 |

| 80 | 138 | 90.5 | 18 | 1.20 |

| 100 | 162 | 116.0 | 20 | 1.58 |

| 125 | 188 | 141.5 | 22 | 2.08 |

| 150 | 218 | 170.5 | 24 | 2.73 |

| 200 | 278 | 221.5 | 26 | 4.52 |

| 250 | 335 | 276.5 | 26 | 5.73 |

| 300 | 395 | 327.5 | 28 | 8.42 |

| 350 | 450 | 359.5 | 32 | 14.5 |

| 400 | 505 | 411.0 | 34 | 18.0 |

| 450 | 555 | 462.0 | 36 | 21.0 |

| 500 | 615 | 513.5 | 38 | 26.8 |

| 600 | 720 | 616.5 | 40 | 34.1 |

| DN | d mm | B mm | F mm | Mass kg |

|---|---|---|---|---|

| 10 | 40 | 18.0 | 12 | 0.094 |

| 15 | 45 | 22.0 | 12 | 1.114 |

| 20 | 58 | 27.5 | 14 | 0.225 |

| 25 | 68 | 34.5 | 14 | 0.296 |

| 32 | 78 | 43.5 | 14 | 0.362 |

| 40 | 88 | 49.5 | 14 | 0.457 |

| 50 | 102 | 61.5 | 16 | 0.653 |

| 65 | 122 | 77.5 | 16 | 0.876 |

| 80 | 138 | 90.5 | 18 | 1.20 |

| 100 | 162 | 116.0 | 20 | 1.58 |

| 125 | 188 | 141.5 | 22 | 2.08 |

| 150 | 218 | 170.5 | 24 | 2.73 |

| 200 | 285 | 221.5 | 28 | 5.55 |

| 250 | 345 | 276.5 | 30 | 7.87 |

| 300 | 410 | 327.5 | 34 | 12.8 |

| 350 | 465 | 359.5 | 36 | 19.3 |

| 400 | 535 | 411.0 | 42 | 28.4 |

| 450 | 560 | 462.0 | 46 | 30.4 |

| 500 | 615 | 513.5 | 50 | 35.3 |

| 600 | 735 | 616.5 | 54 | 53.3 |

Tolerances: For size ≤ DN 250, d (-1.0mm, +2.0mm); for size > DN 250, d (-1.0mm, +3.0mm). For size ≤ DN 100, B (-0mm, +0.5mm); for DN 100 < size ≤ DN 400, B (-0mm, +1.0mm); for DN 400 < size ≤ DN 600, B (-0mm, +1.5mm). For F ≤ 18mm, F (-1.3mm, +1.0mm); for F > 18mm, F (-1.5mm, +1.5mm).