Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

Commercially pure titanium is unalloyed titanium with small traces of impurities such as carbon, hydrogen, iron, nitrogen, and oxygen. It is classified into four ASTM grades: Grade 1, Grade 2, Grade 3 and Grade 4, which have varying amounts of impurities. The CP titanium generally has more than 1000 ppm oxygen and iron, nitrogen, carbon, and silicon as principal impurities. Because small amounts of interstitial impurities greatly affect the mechanical properties of pure titanium, it is not convenient to distinguish the various grades of unalloyed titanium on the basis of chemical analysis. Titanium mill products are more readily distinguished by mechanical properties.

Commercially pure titanium round bars made of ASTM B348 Grade 3.

For ASTM Grade 1, 2, 3, 4 in sequence, as the impurity content goes up, the corrosion resistance, room-temperature ductility and formability are reduced but the strength goes higher. In general, commercially pure (CP) titanium is useful in applications requiring high ductility for fabrication as well as high corrosion resistance and good weldability but relatively low strength in service.

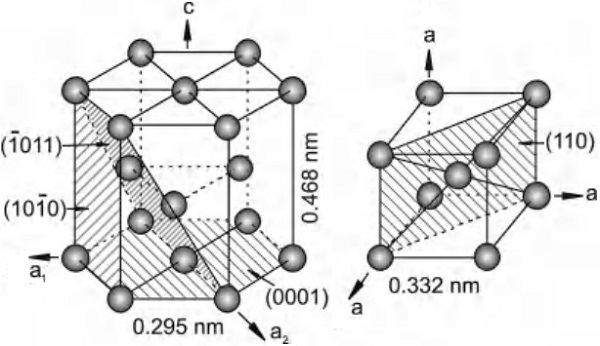

Commercially pure titanium has several crystal structures, each of which is only stable within particular temperature ranges. The complete transformation from one into another crystal structure is called allotropic transformation; the respective transformation temperature is called the transus temperature. Pure titanium crystallizes at low temperatures in a modified ideally hexagonal close-packed (hcp) structure, called α titanium. At high temperatures, however, the body-centered cubic (bcc) structure is stable and is referred to as β titanium. The atomic unit cells of the hexagonal close packed (hcp) α titanium and the body-centered cubic (bcc) β titanium are schematically shown in the figure below with their most densely packed planes and directions highlighted.

The unit cells of α (hcp) & β (bcc) phase for pure titanium.

The transformation temperature from one phase to another can be raised or lowered depending on the type and amount of impurities. The presence of impurities in CP titanium divides the single temperature for equilibrium transformation into two temperatures: the α transus temperature, below which the alloy is all-alpha; and beta transus temperature, above which the alloy is all-beta. Between these temperatures, both alpha and beta are present.

| ASTM Designation | α Transus °C [°F] | β Transus °C [°F] |

|---|---|---|

| Grade 1 | 880 [1620] | 888 [1630] |

| Grade 2 | 890 [1635] | 913 [1675] |

| Grade 3 | 900 [1650] | 920 [1685] |

| Grade 4 | 905 [1660] | 950 [1740] |

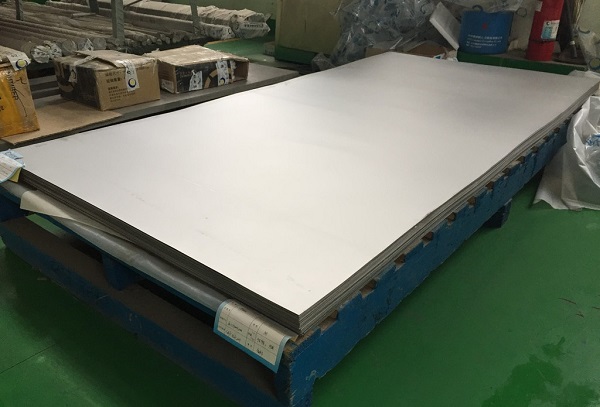

ASTM B265 titanium Grade 2 sheets, 2.5m x 1.5m x 5mm, delivered to Illinois, the US.

| Standard | Product Form |

|---|---|

| ASTM B265 | plate, sheet, strip |

| ASTM B348 | bar, billet |

| ASTM B367 | casting |

| ASTM B381 | forging |

| ASTM F467 | bolt, stud, screw |

| ASTM F468 | nut |

| ASTM B363 | BW fitting |

| ASTM B861 | seamless pipe |

| ASTM B862 | welded pipe |

| ASTM B338 | smls & wld tube |

| Element | ASTM Grade 1 wt. % | ASTM Grade 2 wt. % |

|---|---|---|

| C | ≤0.10 | ≤0.10 |

| H | ≤0.015 | ≤0.015 |

| O | ≤0.18 | ≤0.25 |

| N | ≤0.03 | ≤0.03 |

| Fe | ≤0.20 | ≤0.30 |

| Ti | balance | balance |

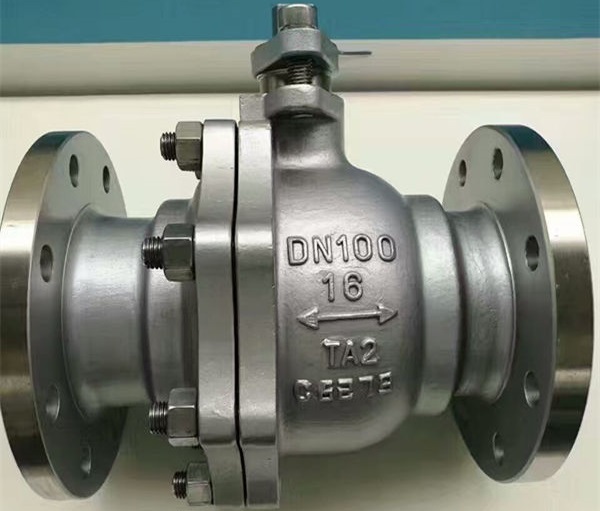

A floating-style ball valve made from CP titanium Grade 2, DN100 PN16 BS 5351.

| Element | ASTM Grade 3 wt. % | ASTM Grade 4 wt. % |

|---|---|---|

| C | ≤0.10 | ≤0.10 |

| H | ≤0.015 | ≤0.015 |

| O | ≤0.35 | ≤0.40 |

| N | ≤0.05 | ≤0.05 |

| Fe | ≤0.30 | ≤0.50 |

| O.T. | ≤0.40 | 0.40 |

| Ti | balance | balance |

| ASTM Designation | Tensile Strength min. MPa [ksi] | Yield Strength MPa [ksi] | Elongation min. % |

|---|---|---|---|

| Grade 1 | 240 [35] | 170-310 [25-45] | 24 |

| Grade 2 | 345 [50] | 275-450 [40-65] | 20 |

| Grade 3 | 440 [64] | 380-550 [55-80] | 18 |

| Grade 4 | 550 [80] | 480-655 [70-95] | 18 |