Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

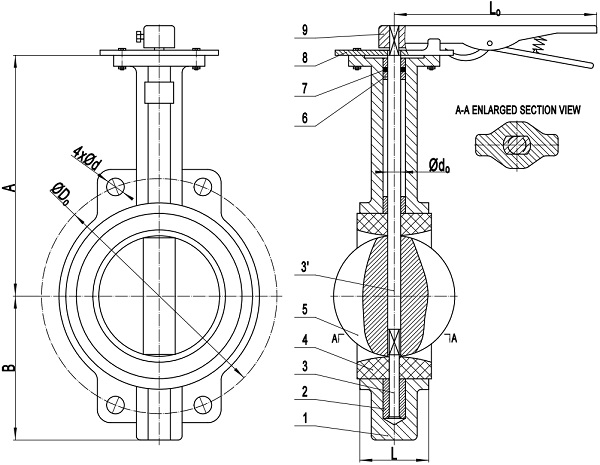

The technical drawing of wafer type butterfly valve without pin.

Wafer type butterfly valves, either made of cast grey iron or ductile iron, can be further classified according to the way its disc is attached to the shaft. If the disc is attached to the shaft by using a through taper pin, it is called pinned disc or disc with pin; If the disc is attached to the shaft by profile connection rather than by using taper pins, as illustrated in the drawing above, it is called disc without pin or pinless disc. The wafer type butterfly valves without pin can be designed in compliance with ISO 5752, BS 5155, EN 593, DIN 3202, MSS SP 67, or API 609, etc. They are available in sizes DN50 to DN300 and are generally used for low pressure services. (1) The valve is furnished with a single through shaft that has a reduced diameter at one end. (2) The soft seat is made of rubber such as EPDM, NBR and Viton. The rubber may be lined to the valve body prior to vulcanization so that it adheres to the body internal surface firmly. (3) The valve is handle/ lever operated with position indicator and locking device. As a quarter-turn rotary-motion valve, it not only has 0° (fully closed) and 90° (fully open) for on-off services but also has 8 uniformly distributed other positions for throttling services. (4) Nickel plated ductile iron disc provides good resistance to corrosion and erosion with relatively low cost.

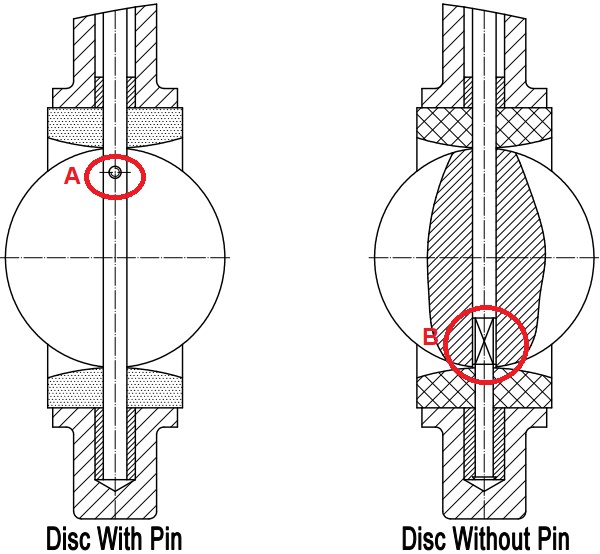

In the pinned disc design, both the disc and the shaft are drilled with a through hole. The taper pin inserts through the hole and firmly attaches the disc to the shaft by interference fit. It is shown at position A in the illustration below. The machining and assembly of a pinned disc are very easy and convenient. However, there are some disadvantages: (1) After prolonged service and frequent operation, the pin might be subject to cracking due to fatigue resulting in malfunction of the wafer butterfly valve. (2) Crevice corrosion might occur at the contact surfaces between the taper pin and the hole. It may further cause leakage at fully closed position or possible back seat leakage.

The illustration of pinned disc versus disc without pin design.

In conventional design, the “pinless” wafer butterfly valve also has a single through shaft. Instead of using a taper pin, the disc is designed without pin. A short length at the lower section of shaft (at position B in the illustration) is furnished with a pair of flat faces, which form “profile connection” with the disc bore that also has been machined to flat faces. The torque can be delivered from the shaft to the disc via this profile connection. This pinless design eliminates the disadvantages brought by a pinned disc. Besides, it can be replaced and assembled more conveniently. The lower section of shaft that extends downward from the profile connection has a reduced diameter. Thus, this conventional disc-without-pin design is limited to low-pressure services.

Ductile iron wafer type butterfly valve without pin, handle operated with indicator & locking device, Ni-plated ductile iron disc, black coated.

| Item No. | Part Name | Material Spec. |

|---|---|---|

| 1 | Body | Cast Iron Ductile Iron |

| 2 | Long Bushing | Bronze, PTFE |

| 3 & 3' | Shaft | SS 304, SS 316 SS 416, SS 431 |

| 4 | Seat | EPDM, NBR, Viton, PTFE |

| 5 | Disc | SS 304, SS 316, Bronze, Al-Bronze D.I. + Ni Plated |

| 6 | Short Bushing | Bronze, PTFE |

| 7 | O-Ring | EPDM, NBR |

| 8 | Indicator | C.S. + Galv. |

| 9 | Handle Lever | C.I., Aluminum |

| Size | B mm | A mm | L mm |

|---|---|---|---|

| 2" | 80 | 161 | 42 |

| 2-1/2" | 89 | 175 | 45 |

| 3" | 95 | 181 | 45 |

| 4" | 114 | 200 | 51 |

| 5" | 127 | 213 | 55 |

| 6" | 139 | 226 | 55 |

| 8" | 175 | 260 | 60 |

| 10" | 203 | 292 | 67 |

| 12" | 242 | 337 | 76 |