Product Categories

- Products (61)

Cement mortar lined steel flanges for waterworks service. The cement mortar lining shall be furnished in compliance with AWWA C-205.

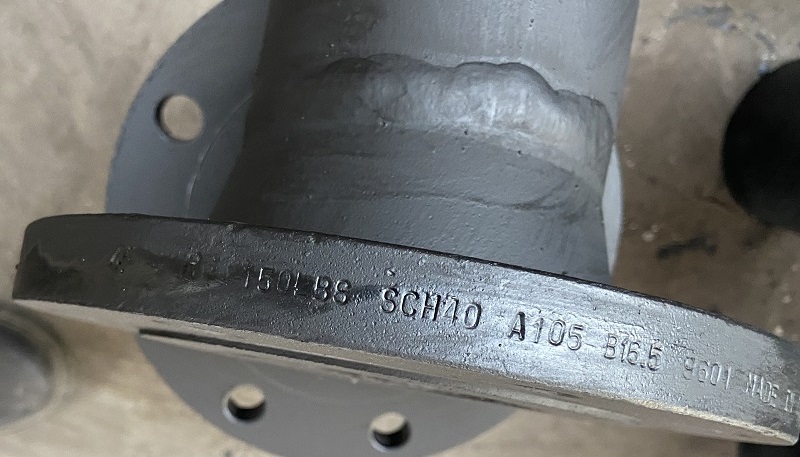

Cement mortar lined welding neck flanges for a water supply project in Doha, Qatar. The flange is welded with an extension of straight pipe length. Both interior surfaces are cement lined.

The cement mortar lined steel flanges are piping flanges used for waterworks services, which combine the physical strength of steel with the corrosion-resistant and protective qualities of cement mortar. The cement-mortar lining applied manually creates a smooth, dense finish that protects the flange interior surface from tuberculation and provides a measure of corrosion protection. The smooth interior surface will provide a high flow coefficient for design life of the flange under normal operating conditions. In addition, the cement-mortar lining results in a tough, durable, and rugged coating that forms an alkaline environment where oxidation or corrosion of the steel is inhibited. The cement-mortar lined steel flanges are usually welded to steel water pipes also lined with cement mortar, both of which shall comply with AWWA C205.

The steel flange is usually made from ASTM A105 forging in accordance with ASME B16.5, ASME B16.47 or AWWA C207. Cement for mortar shall conform to ASTM C150. It shall be stored in a weather-tight, dry, well ventilated structure. Fine aggregate for cement mortar shall consist of natural sand or sand obtained by crushing stone or gravel and shall comply with the requirements of ASTM C33. For cement-mortar-lining thickness 1/2″ (12.7 mm) or less, 100% of the fine aggregate shall pass a US standard service No.4. The water used for cement mortar and for curing linings shall conform to the applicable requirements of ASTM C94. The curing compound for curing cement-mortar linings shall comply with ASTM C309.

The interior surface of the bore diameter of cement-mortar lined steel flange.

The surface to be cement-mortar lined shall be cleaned to remove loose or other foreign matter that could interfere with the adherence of the cement mortar. Cement mortar shall be composed of cement, sand, and water, well mixed and of proper consistency to obtain a dense, homogeneous lining that will adhere firmly to the interior surface of the steel flange. It shall consist of one part cement to not more than three parts fine aggregate (sand) by weight. Enough water shall be added to obtain proper placement characteristics of the batched cement mortar. The free water content of the cement-mortar lining mix shall not exceed 7.5 gal (28.4 L) per 94 lb (43 kg) of cement. The placement of cement-mortar lining to flange interior surface shall be accomplished by hand application and finished to produce a smooth and dense surface. The lining shall be uniform in thickness and lining thicknesses shall be as listed in the table below. Ends of lining shall be left square and uniform with regard to the longitudinal axis of the pipe. The cement-mortar linings shall be cured in a curing area immediately after completion of hand placement. After the curing process, the exterior surface of the flange shall be painted according to purchaser’s specification.

| NPS | Lining Thickness | Tolerance |

|---|---|---|

| 4"~10" | 1/4" [6mm] | (-1/16", +1/8") (-1.6mm, +3.2mm) |

| 11"~23" | 5/16" [8mm] | (-1/16", +1/8") (-1.6mm, +3.2mm) |

| 24"~36" | 3/8" [10mm] | (-1/16", +1/8") (-1.6mm, +3.2mm) |

| Over 36" | 1/2" [13mm] | (-1/16", +3/16") (-1.6mm, +4.8mm) |

The marking of the cement lined flange. ASTM A105, ASME B16.5 Class 150 4″ WNRF SCH40.

(1) The cement-mortar linings are best suited for steel flanges that are continuously filled with water. Soft, aggressive waters, as well as prolonged contact with heavily chlorinated water, may be injurious to cement-mortar linings. The water-soluble chloride ion content of the lining mix, expressed as a percentage of the weight of cement, shall not exceed 0.15%. (2) The flow velocity usually shall not exceed 6.1 m/s. (3) Consideration should be given to limiting the maximum strains (stresses) developed in the steel cylinder of cement-mortar lined steel flange from internal pressure to ensure long-term design life of the system.