Product Categories

- Products (61)

A seamless butt-welding tee made of ASTM A815 Gr. WPS32750 (duplex alloy 2507); 6" x 3" SCH 10S; ASME B16.9; supplied to a seawater desalination project in Costa Rica.

Alloy 2205 (UNS S32205) seamless elbows, long radius, DN80 SCH10S, ASME B16.9/ ASTM A815 WPS32205.

Shijiazhuang Metalsin supplies a variety of seamless and welded duplex stainless steel pipe fittings made in accordance with ASTM A815. Of all duplex grades covered by the standard specification, four grades are most widely used for the construction of pipe fittings in engineering practice: UNS S31803, UNS S32205, UNS S32750, and UNS S32760. Both S31803 and S32205 are standard duplex stainless steels with the designation “alloy 2205”. S32205 is a modified version of S31803 by keeping chromium, molybdenum and nitrogen levels in the higher half of the ranges of S31803. The narrower composition range results in optimum corrosion resistance and avoidance of detrimental intermetallic phases. Alloy 2205 pipe fittings provided by Shijiazhuang Metalsin are always S31803/ S32205 dual certified. Both S32750 (alloy 2507) and S32760 are designated as super duplex stainless steels because of their higher pitting resistance equivalent number (PREN), which is usually in the range of 40~43. They exhibits greatly improved resistance to chloride stress-corrosion cracking (SCC).

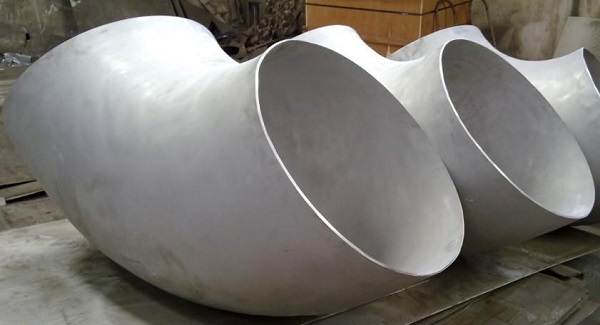

Elbow S/R STD; 30″ BW ASME B16.9; ASTM A815 WP-WX S32760; made of DSS plates; all welds shall be 100% X-ray inspected.

ASTM A815 duplex stainless steel pipe fittings can be classified into two general classes: WP and CR. Class CR fittings are those manufactured to the requirements of MSS SP-43, and they are used for low pressure, corrosion resistant application. Class WP fittings are subdivided into four subclasses: Class WP-S, Class WP-W, Class WP-WX, Class WP-WU. They should be manufactured to the requirements of ASTM A960. Further, Class WP fittings are primarily made in accordance with ASME B16.9. Class WP-S fittings are those manufactured from seamless product by a seamless method of manufacture; Class WP-W fittings are those which contain welds where the fitting fabrication or construction welds have been radiographed; Class WP-WX fittings are those which contain welds where all welds have been radiographed; Class WP-WU fittings are those which contain welds where all welds have been ultrasonically tested. Duplex stainless steel pipe fittings made in accordance with ASTM A815 may be furnished in a variety of shapes or types such as elbow, tee, reducer, return, bend, cap, stub end, cross, nipple, saddle, and coupling, etc.

| EL. | S31803 | S32205 | S32750 | S32760 |

|---|---|---|---|---|

| C | ≤0.030 | ≤0.030 | ≤0.030 | ≤0.030 |

| Mn | ≤2.00 | ≤2.00 | ≤1.20 | ≤1.00 |

| P | ≤0.030 | ≤0.030 | ≤0.035 | ≤0.030 |

| S | ≤0.020 | ≤0.020 | ≤0.020 | ≤0.010 |

| Si | ≤1.00 | ≤1.00 | ≤0.80 | ≤1.00 |

| Ni | 4.5-6.5 | 4.5-6.5 | 6.0-8.0 | 6.0-8.0 |

| Cr | 21.0-23.0 | 22.0-23.0 | 24.0-26.0 | 24.0-26.0 |

| Mo | 2.5-3.5 | 3.0-3.5 | 3.0-5.0 | 3.0-4.0 |

| Cu | - | - | ≤0.50 | 0.50-1.00 |

| N | 0.08-0.20 | 0.14-0.20 | 0.24-0.32 | 0.20-0.30 |

| W | - | - | - | 0.50-1.00 |

| Item | S31803 | S32205 | S32750 | S32760 |

|---|---|---|---|---|

| Yield Strength min. MPa [ksi] | 450 [65] | 450 [65] | 550 [80] | 550 [80] |

| Tensile Strength min. MPa [ksi] | 620 [90] | 655 [95] | 800 [116] | 750 [109] |

| Elongation in 2" min. % | 20.0 | 20.0 | 15.0 | 25.0 |

| HBW, max | 290 | 290 | 310 | 270 |

The material for pipe fittings shall consist of forgings, bars, plates, seamless or welded tubular products that confirm to the chemical requirements of relative duplex grades. Duplex stainless steel pipe fittings made to ASTM A815 shall be formed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, fusion welding, machining or by combination of two or more of these operations. Most duplex stainless steel pipe fittings shall be made by a cold forming process such as cold forming of elbows and bends through a die under hydraulic pushing force, cold pressing of reducers and caps, cold extruding of tees. Since duplex stainless steels have much higher strength than common austenitic stainless steels, the power of the cold forming machine shall be sufficient enough to initiate the deformation. In addition, duplex stainless steels are also strongly work hardened as they are deformed. This rapid increase in strength during cold deformation shall be taken into account when determining the maximum material thickness that can be formed on the equipment. When the thickness is too heavy to be cold formed, the hot forming process shall apply. The hot forming temperature shall be controlled between 1100°C [2000°F] and 1150°C [2100°F]. At this temperature range, the duplex stainless steel is soft or ductile enough to be formed but not too soft so that warping or distortion can be avoided. And the increased tendency to form scale above 1150°C can be suppressed.

A hydraulic cold forming machine for the manufacture of duplex & austenitic stainless steel elbows and bends.

A welding process is necessary for large-diameter duplex stainless steel pipe fittings which are made from plates. The welded fittings shall have the welders, welding operators, and welding procedures qualified under the provisions of Section IX of ASME Boiler and Pressure Vessel Code. They shall also meet all relative requirements specified by Section VIII Division 1 of ASME BPVC. After the forming process, it is necessary to perform a full solution anneal followed by a rapid quench to fully restore the mechanical properties and corrosion resistance. According to ASTM A815, the solution annealing temperature ranges for UNS S31803, S32205, S32750 and S32760 are 1870°F-2010°F [1020°C-1100°C], 1870°F-2010°F [1020°C-1100°C], 1920°F-2060°F [1025°C-1125°C], 2010°F-2085°F [1100°C-1140°C], respectively.

Visual inspection, dimensional examination, tensile test, hardness test, X-ray inspection, proof test, ultrasonic test, liquid penetrant test, detection of detrimental intermetallic phases according to ASTM A923 (Method A, Method B, Method C).