Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

Pressure vessel plates, ASME A537 Class 1, 2.5 m x 1.2 m x 32 mm.

The ASTM A537 Class 1 steel plate with a thickness no greater than 64 mm [2-1/2″] can be applied to ASME B31.3 process piping. The plates shall be normalized with minimum yield strength and tensile strength of 50 ksi [345 MPa] and 70 ksi [485 MPa], respectively. The UNS designation of ASTM A537 Class 1 is K12437 and its P-Number is 1. The B31.3 Code has endorsed three other product forms equivalent to ASTM A537 Class 1 including ASTM A671 Gr. CD70 eletric-fusion-welded (EFW) steel pipes for atmospheric and lower temperatures, ASTM A672 Gr. D70 electric-fusion-welded (EFW) steel pipes for high-pressure service at moderate temperatures, and ASTM A691 Gr. CMSH-70 EFW steel pipes for high-pressure service at high temperatures.

| *Temp. | *S |

|---|---|

| Min. ~100 | 23.3 |

| 200 | 23.3 |

| 300 | 22.8 |

| 400 | 22.7 |

| 500 | 22.7 |

| 600 | 22.4 |

| 650 | 21.9 |

| 700 | 18.3 |

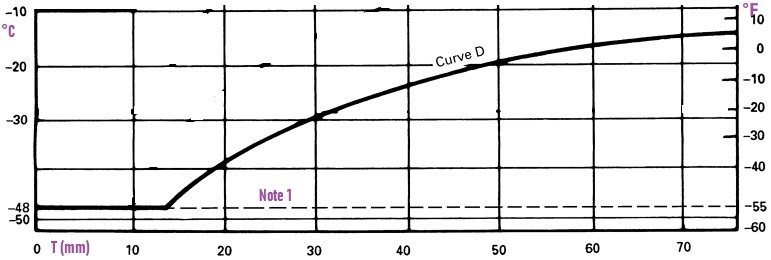

Figure-1: Curve-D for minimum temperatures without impact testing for ASTM A537 Cl.1; Note 1: impact testing is required for any design minimum temperature below -48°C [-55°F].

The maximum use temperature of ASTM A537 Class 1 steel is 371°C [700°F]. According to ASME B31.3, the minimum use temperature shall be determined by a minimum temperature-thickness curve, Curve D. As illustrated in Figure-1, the left vertical axis is design minimum temperature in °C while the right vertical axis is design minimum temperature in °F. The horizontal axis represents nominal thickness T, in mm unit. If a design minimum temperature-thickness combination is on or above the curve, impact testing may be exempted. The tabulated values for minimum temperatures without impact testing for ASTM A537 Class 1 material are presented in the table below.

| T mm | T inch | Curve D °C | Curve D °F |

|---|---|---|---|

| 6.4 | 0.25 | -48.3 | −55 |

| 7.9 | 0.3125 | -48.3 | −55 |

| 9.5 | 0.375 | -48.3 | −55 |

| 10.0 | 0.394 | -48.3 | −55 |

| 11.1 | 0.4375 | -48.3 | −55 |

| 12.7 | 0.5 | -48.3 | −55 |

| 14.3 | 0.5625 | −45.6 | −55 |

| 15.9 | 0.625 | −43.9 | -47 |

| 17.5 | 0.6875 | −41.7 | -43 |

| 19.1 | 0.75 | −40.0 | -40 |

| 20.6 | 0.8125 | −38.3 | -37 |

| 22.2 | 0.875 | −36.7 | -34 |

| 23.8 | 0.9375 | −35.6 | -32 |

| 25.4 | 1.0 | −34.4 | -30 |

| 27.0 | 1.0625 | −33.3 | -28 |

| 28.6 | 1.125 | −32.2 | -26 |

| 30.2 | 1.1875 | −30.6 | -23 |

| 31.8 | 1.25 | −29.4 | -21 |

| 33.3 | 1.3125 | −28.3 | -19 |

| 34.9 | 1.375 | −27.8 | -18 |

| 36.5 | 1.4375 | −26.7 | -16 |

| 38.1 | 1.5 | −25.6 | -14 |

| 39.7 | 1.5625 | −25.0 | -13 |

| 41.3 | 1.625 | −23.9 | -11 |

| 42.9 | 1.6875 | −23.3 | -10 |

| 44.5 | 1.75 | −22.2 | -8 |

| 46.0 | 1.8125 | −21.7 | -7 |

| 47.6 | 1.875 | −21.1 | -6 |

| 49.2 | 1.9375 | −20.6 | -5 |

| 50.8 | 2.0 | −20.6 | -4 |

| 52.4 | 2.0625 | −19.4 | -3 |

| 54.0 | 2.125 | −18.9 | -2 |

| 55.6 | 2.1875 | −18.3 | -1 |

| 57.2 | 2.25 | −17.8 | 0 |

| 58.7 | 2.3125 | −17.2 | 1 |

| 60.3 | 2.375 | −16.7 | 2 |

| 61.9 | 2.4375 | −16.1 | 3 |

| 63.5 | 2.5 | −15.6 | 4 |

| 65.1 | 2.5625 | −15.0 | 5 |

| 66.7 | 2.625 | −14.4 | 6 |

| 68.3 | 2.6875 | −13.9 | 7 |

| 69.9 | 2.75 | −13.3 | 8 |

| 71.4 | 2.8125 | −13.3 | 8 |

| 73.0 | 2.8125 | −12.8 | 9 |

| 74.6 | 2.9375 | −12.2 | 10 |

| 76.2 | 3.0 | −11.7 | 11 |