Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

Metalsin Tech supplies a variety of electric-fusion-welded (EFW) austenitic chromium-nickel alloy steel (stainless steel) pipes made in accordance with ASTM A358. The EFW process produces a uniform and consistent weld and pipe wall, crucial for maintaining the pipe’s integrity under high-temperature, high-pressure, and corrosive conditions. These pipes are intended for severe service such as petrochemical, chemical, oil and gas, pharmaceutical, and power generation industries. We can manufacture and supply EFW stainless steel pipes in sizes Φ8mm – Φ3600mm with wall thicknesses ranging from 0.2mm – 120mm.

ASTM A358 EFW pipes shall be made from a wide range of austenitic stainless steel plates conforming to ASTM A240. Some most commonly used material grades include N08020, N08367, Alloy 800 (N08800), Alloy 800H (N08810), N08904, N08926, 201 (S20100), 304 (S30400), 304L (S30403), 304H (S30409), 304N (S30451), 304LN (S30453), 309S (S30908), 310S (S31008), S31254, 316 (S31600), 316L (S31603), 316H (S31609), 316N (S31651), 316LN (S31653), 317 (S31700), 317L (S31703), 321 (S32100), 347 (S34700), 347H (S34709), 348 (S34800).

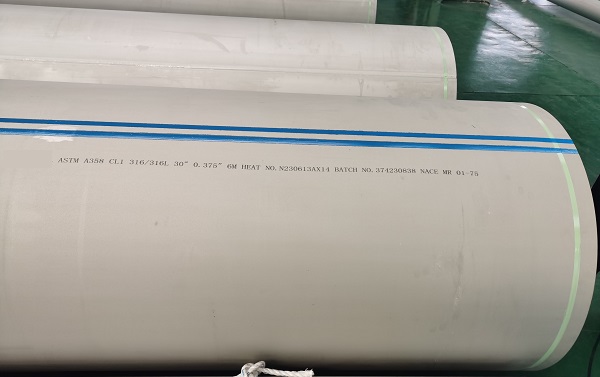

ASTM A358 EFW dual-certified 316/316L stainless steel pipes, supplied to a Petronas project in Malaysia.

These austenitic stainless steels used in ASTM A358 EFW pipes, conforming to ASTM A240, offer a range of shared advantages including excellent corrosion resistance, high-temperature strength, and outstanding weldability, making them ideal for demanding applications in corrosive and high-temperature environments. These steels maintain their mechanical integrity even under stress, provide versatility for various industrial uses, and feature hygienic properties suitable for sensitive applications like pharmaceuticals. Their durability, combined with low maintenance requirements, ensures a long service life and reliable performance across critical systems.

ASTM A358 EFW stainless steel pipes are classified into five different classes based on the manufacturing process:

ASTM A358 Class 1, EFW 316/316L pipes, 30″ STD 6m, conforming to NACE MR 01-75.

The manufacture process of ASTM A358 EFW stainless steel pipes involves the following steps:

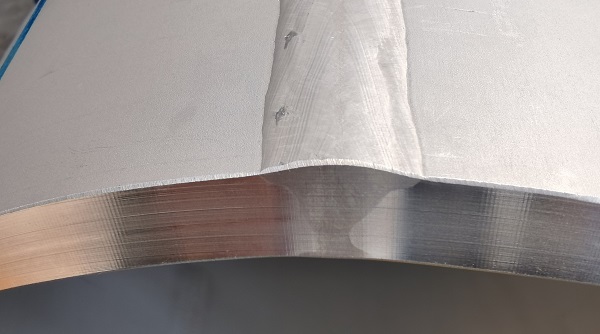

The double-welded seam of a ASTM A358 EFW stainless steel pipe: a weld seam that is formed from both outside and inside of the pipe.

According to ASTM A358, EFW stainless steel pipes may be furnished in single welded or double welded condition. Single welded pipes involve welding from only one side (outer side of the pipe), typically using filler material, and require full radiographic examination to ensure weld integrity. They are suitable for thinner-walled pipes or when access is limited. Double welded pipes are welded from both sides (inner and outer sides of the pipe), ensuring complete penetration and greater strength, with varying degrees of radiographic testing based on the pipe class. These are preferred for thicker-walled pipes and high-pressure or high-temperature applications. Among all classes, ASTM A358 Class 1 double-welded pipes with complete X-ray inspection are the most widely used EFW stainless steel pipes.