Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

ASTM A335 P1, P11, and P22 are three typical grades of seamless ferritic alloy steel pipes for high-temperature service, known as heat-resistant and creep-resistant low alloy steels. The nominal composition of grade P1, P11, and P22 of ASTM A335 are C-0.5Mo, 1.25Cr-0.5Mo , and 2.25Cr-1Mo, respectively. These alloy steel pipes are widely used in oil refineries, chemical industries, and electrical power generation plants for piping and pressure vessels. Due to the different Cr-Mo alloying contents, the three grades have different maximum application temperatures.

ASTM A335 P11 seamless pipes, 12″ SCH80 in various length, supplied to Kuwait.

ASTM A335 Grade P1 (UNS K11522):

ASTM A335 Grade P11 (UNS K11597):

ASTM A335 Grade P22 (UNS K21590):

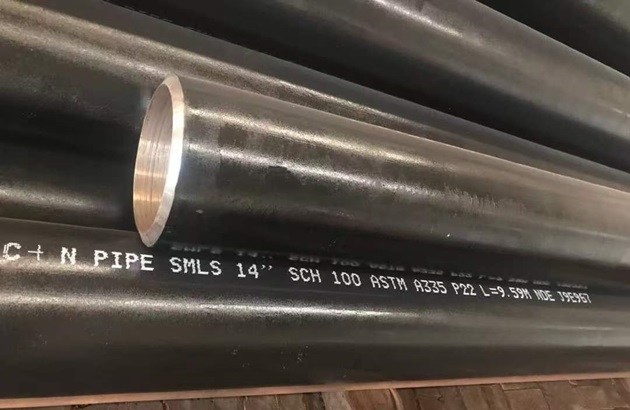

ASTM A335 P22 seamless pipes, 14″ SCH100 L=9.59m, supplied to Mexico.

ASTM A335 Grade P1:

ASTM A335 Grade P11:

ASTM A335 Grade P22:

Grade P1 of ASTM A335, also known as 0.5Mo steel, contains 0.5% molybdenum for enhanced creep strength. When used at temperatures above 455°C [850°F], 0.5Mo steel is susceptible to spheroidization and graphitization. Spheroidization refers to the transformation of carbide particles in steel into a more spherical shape, which can weaken the steel by reducing its strength and hardness. Graphitization involves the formation of free graphite within the steel, which can lead to embrittlement, decreasing the material’s toughness and increasing the likelihood of failure under stress.

Various seamless Cr-Mo alloy steel pipes made in accordance with ASTM A335/ ASME SA-335.

Both grade P11 (1.25Cr-0.5Mo) and P22 (2.25Cr-1Mo) of ASTM A335 are chromium-molybdenum alloy steels. The main advantage of these steels is the improved creep strength from molybdenum and chromium additions and the enhanced corrosion resistance from chromium. The creep strength of chromium-molybdenum steels is derived mainly from two sources: solid-solution strengthening of the matrix ferrite by carbon, molybdenum, and chromium: and precipitation hardening by carbides. The effects of chromium and molybdenum on creep strength are complex. Creep strength generally, but not always, increases with higher amounts of molybdenum and chromium. While grade P11 of ASTM A335 (1.25Cr-0.5Mo) is used up to 590°C [1100°F], grade P22 (2.25Cr-1Mo) offers better oxidation resistance and creep strength than P1 and P11 steel. The 2.25Cr-1Mo steel is a highly favored alloy steel for service up to 650 °C (1200 °F) without the presence of hydrogen or 480 °C (900 °F) in a hydrogen environment.