Product Categories

- Products (61)

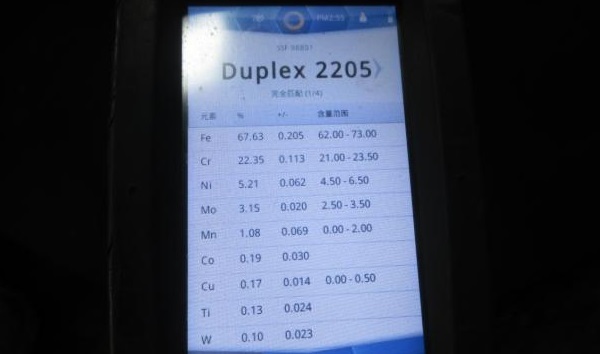

The PMI (spectroscopic analysis) test result for the ASTM A182 Gr. F60 flange.

ASTM A182 Grade F60 is a standard duplex stainless steel forging grade. It has the same nominal composition 22Cr–5Ni–3Mo–N as ASTM A182 Gr. F51 but with narrower actual composition limits. Both Gr. F51 and Gr. F60 of ASTM A182 are called “alloy 2205” or “duplex 2205”, however, the UNS number of the former is S31803 while that of the latter is S32205. The composition range that was originally set for alloy 2205 (S31803) was too broad. Experience has shown that for optimum corrosion resistance and to avoid intermetallic phases, the chromium, molybdenum and nitrogen levels should be kept in the higher half of the ranges for S31803. Therefore, a modified 2205 with a narrower composition range was introduced with the UNS number S32205.

The marking of a welding neck flange made of ASTM A182 Gr. F60 (S32205), manufactured in accordance with ASME B16.5 Class 600.

Although neither ASME B16.5 nor ASME B16.47 has endorsed ASTM A182 F60 as a listed material, they have endorsed the use of ASTM A182 F51 as flange material. ASTM A182 F60 flanges can be treated as flanges made of ASTM A182 F51 with narrower composition range. The pressure-temperature ratings for ASTM A182 F51 flanges are also applicable to ASTM A182 F60 flanges. In this situation, ASTM A182 F60 can be viewed as S31803/ S32205 dual certified grade.

| Element | Composition, % |

|---|---|

| C | ≤0.030 |

| Mn | ≤2.00 |

| P | ≤0.030 |

| S | ≤0.020 |

| Si | ≤1.00 |

| Ni | 4.5–6.5 |

| Cr | 22.0–23.0 |

| Mo | 3.0–3.5 |

| N | 0.14–0.20 |

| Tesile Test | Requirements |

|---|---|

| Tensile Strength min. MPa [ksi] | 655 [95] |

| Yield Strength min. MPa [ksi] | 450 [65] |

| Elongation in 2", min. % | 25 |

| Reduction of Area, min. % | 45 |

ASTM A182 F60 flanges shall be made by a hot forging process. The steel shall be forged as close as practicable to the specified shape and size of the flange. The optimum forging temperature shall be controlled between 1100°C [2000°F] and 1150°C [2100°F]. If the forging temperature is higher than 1150°C [2100°F], it may affect the dimensional stability of the work piece and there is increased tendency to form scale above this temperature. If the forging temperature is much lower than 1100°C [2000°F], a considerable amount of detrimental intermetallic phases may develop which can result in cracking in the deformed region. After hot forging, ASTM A182 F60 flanges shall be solution treated at a temperature no less than 1870°F [1020°C]. The flanges shall be soaked at this temperature for a time long enough to dissolve any intermetallic precipitates. After the full solution annealing, a rapid quench shall be followed.

ASTM A182 F60 flanges exhibits excellent resistance to pitting corrosion especially in chloride containing solutions. The primary elements that contribute to the pitting corrosion resistance are chromium (Cr), molybdenum (Mo) and nitrogen (N). An index for comparing the resistance to localized pitting attack is developed in terms of these elements. The index is called pitting resistance equivalent number (PREN). The PREN of ASTM A182 Gr. F60 is defined, in weight percent, using the following equation: PREN = Cr + 3.3Mo + 16N. The higher the PREN, the better the performance of the ASTM A182 F60 flange in chloride environments.

Dimensional examination, visual inspection, tensile test, heat analysis, PMI, detection of detrimental phases according to ASTM A923, pitting and crevice corrosion resistance test according to ASTM G48, ultrasonic test, dye penetration inspection.