Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

The ASME B16.5 RTJ flanges refers to pipe flanges manufactured in accordance with ASME B16.5 furnished with a ring-type joint facing. The ring-type joint facing, also known simply as ring joint facing, is an additional raised portion furnished to various flange types to form a one-piece flange. A deep ring-shaped groove shall be cut into the flange contact surface. Instead of conventional flat or spiral wound gaskets, a metallic ring gasket with oval or octagonal cross section is used to rest in the deep groove. As the bolts are tightened, the metallic ring is compressed, creating a tight seal.

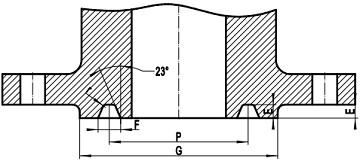

Figure-1: the typical drawing of an ASME B16.5 flange with a ring-type joint (RTJ) facing.

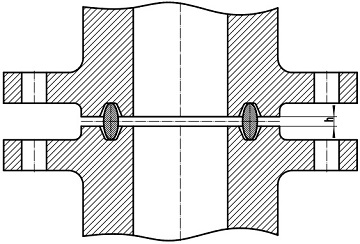

The seal between two RTJ flanges is made by plastic deformation of the RTJ gasket into the groove of the flange, resulting in intimate metal-to-metal contact between the ring gasket and the flange groove. The faces of the two opposing RTJ flanges in connection don not come into contact because a gap is maintained by the presence of the ring gasket. The approximate distance between the two flanges are denoted as “h” in Figure-2.

RTJ flanges manufactured in accordance with ASME B16.5 may be provided in various flange types covering welding neck, slip on, socket welding, threaded, blind, long weld neck, and reducing type. They are available in pressure ratings Class 150 through Class 2500. The RTJ facing shall be additional to the minimum flange thickness. The bottom of the ring joint groove shall be in the same plane as the flange edge of a full thickness flange. The ring joint grooves for ASME B16.5 flanges cover a series of groove number ranging from 11 to 79. Since the use of RTJ flanges requires the use of ring joint gaskets. The groove numbers are corresponding to the metallic ring numbers. The metallic ring gaskets shall be fabricated in accordance with ASME B16.20. The side wall surface finish of the gasket groove in the flange shall not exceed 1.6 μm roughness.

The RTJ flange is considered to be the most efficient flange used in process piping systems. The ring and groove design actually uses internal pressures to enhance the sealing capacity of the connecting flanges. Higher the working pressure in the piping system, better the sealing performance. They are specifically applicable to severe services involving high pressures, high temperatures, cyclic stresses & temperatures, low temperatures, and corrosive fluids, etc.

Figure-2: a RTJ joint consisting of two RTJ flanges and a metallic ring gasket which rests in the ring-joint groove.

The most obvious disadvantage of a ring type joint is that this configuration is most expensive. The precise control of machining both the metallic ring gasket and the ring-joint groove in the flange is very costly. Besides, when dismantling ring joint connections, the flange must be forcibly separated to release the ring from the groove. This may require considerable space. In crowded installations, this could cause major problems. Because of this, the ring joint flange is relegated to applications where space for maintenance and replacement are adequate.

As illustrated in Figure-1 and Figure-2, the dimensions of the ring joint facing of ASME B16.5 flanges are denoted as: P – pitch diameter of groove; G – minimum diameter of raised portion; F – upper width of groove; r – radius at bottom of groove; E – depth of groove, equal to height of raised portion; h – approximate distance between flanges; 23°: slope angle of side wall. The tolerances for these dimensions are: E (+0.40 mm, -0.00 mm); F (±0.20 mm); P (±0.013 mm); if r ≤ 2 mm, (+0.8 mm, -0.0 mm); if r > 2, (±0.8 mm); 23° angle (±0.5°).

| RTJ Facings for ASME B16.5 Flanges in Classes | |||

|---|---|---|---|

| 150# | 300# | 400# | 600# |

| 900# | 1500# | 2500# | - |