Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

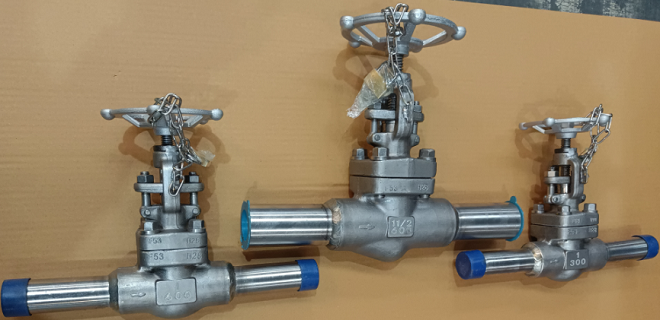

Recently we have supplied a series of API 602 globe valves made of forged super duplex stainless steel S32750 (ASTM A182 F53) to a Middle East client in Jubail, Saudi Arabia. These valves are furnished with socket welding ends with 100mm extension at each end. They feature the metal-seated design in which the seating surfaces are hard faced by Stellite weld overlay. API 602 globe valves are compact, forged steel valves designed for high-pressure and high-temperature applications in the oil, gas, and petrochemical industries. Compliant with the API 602 standard, these valves are typically used in smaller sizes (4 inches and below) and are known for their robust construction, reliability, and tight shut-off capabilities. They feature a linear motion design, making them ideal for throttling and regulating flow, and are available in a wide variety of materials.

API 602 globe valves made of ASTM A182 F53 (S32750), 1“ & 1-1/2” Class 600, socket welding ends with 100mm extension at each end. The seating surfaces are hard-faced by Stellite weld overlay.

ASTM A182 F53 is a duplex stainless steel forging material, also known as UNS S32750 or Super Duplex 2507, widely used in the manufacture of valves for demanding applications. It offers an exceptional combination of high strength, excellent corrosion resistance (particularly against chlorides, acids, and sour environments), and good weldability. Its dual-phase microstructure, comprising both austenite and ferrite, provides superior resistance to stress corrosion cracking, pitting, and erosion. Valves made from ASTM A182 F53 are ideal for harsh environments such as offshore, oil and gas, chemical processing, and power generation, where durability, reliability, and long service life are critical.

| Element | Composition, % |

|---|---|

| C | ≤0.030 |

| Mn | ≤1.20 |

| P | ≤0.035 |

| S | ≤0.020 |

| Si | ≤0.80 |

| Ni | 6.0-8.0 |

| Cr | 24.0-26.0 |

| Mo | 3.0-5.0 |

| N | 0.24–0.32 |

| Cu | ≤0.50 |

| Item | T≤2“ | T>2” |

|---|---|---|

| Tensile Strength min. MPa [ksi] | 785 [114] | 730 [106] |

| Yield Strength min. MPa [ksi] | 525 [76] | 515 [75] |

| Elongation in 2", min. % | 30 | 15 |

| Hardness max. HBW | 310 | 310 |

Stellite weld overlay, also known as Stellite hard facing, is a cobalt-based alloy applied to the seating surfaces of the valve body and disc to enhance wear, erosion, and galling resistance. A layer of Stellite alloy is applied onto the S32750 substrate through welding processes such as TIG, MIG, or plasma arc welding. This method creates a metallurgical bond between the Stellite layer and the base material. Renowned for its exceptional hardness and ability to retain properties at high temperatures, the Stellite layer provides superior protection for sealing surfaces exposed to abrasive or high-stress conditions. By overlaying Stellite onto the seating surfaces, it significantly improves the valve’s durability and service life, ensuring reliable sealing performance even in demanding environments.

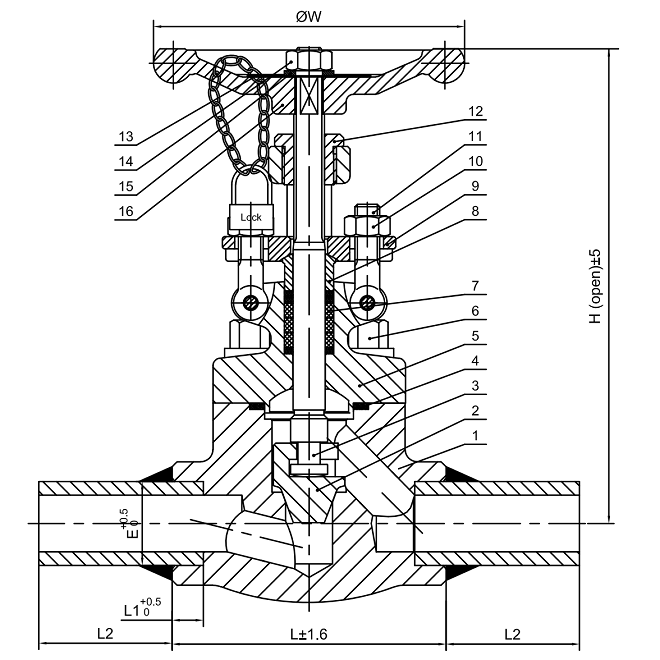

The technical drawing of API 602 metal-seated globe valves, Class 600, handwheel operated, SW end with extension.

| Part No. | Part Name | Material Grade |

|---|---|---|

| 1 | Body | ASTM A182 F53+STL |

| 2 | Disc | ASTM A182 F53+STL |

| 3 | Stem | ASTM A182 F53 |

| 4 | Gasket | S32750+Graphite |

| 5 | Bonnet | ASTM A182 F53 |

| 6 | Hex Bolt | ASTM A193 B8M |

| 7 | Packing | Flexible Graphite |

| 8 | Gland | S32750 |

| 9 | Gland Flange | ASTM A182 F53 |

| 10 | Gland Nut | ASTM A194 8M |

| 11 | Gland Eyebolt | ASTM A193 B8M |

| 12 | Yoke Nut | AISI 1035 |

| 13 | Nameplate | SS304 |

| 14 | Bolt | Stainless Steel |

| 15 | Washer | Stainless Steel |

| 16 | Handwheel | Ductile Iron |

| Size | 2xL2+L | E | H | W |

|---|---|---|---|---|

| 1" | 311 | 33.9 | 207 | 120 |

| 1 1/2" | 352 | 48.8 | 270 | 156 |

API 602 globe valves crafted from ASTM A182 F53 (S32750) material are designed for service in water, oil & gas equipment, conforming to the Class 600 specification. These valves are subject to pressure testing in accordance with API 598 standards, with pressure-temperature according to ASME B16.34. The valves are classified at Class 600, featuring a shell test pressure of 15.0 MPa. The upper seal pressure test, as well as the seal pressure test, are both set at 11.0 MPa. The air test pressure is maintained at 0.6 MPa. The working temperature range for these valves extends from -29 to 315℃.