Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

In the mining and processing of copper, knife gate valves play an essential role in the slurry transportation system. Metalsin Tech specializes in designing and custom manufacturing through-conduit knife gate valves (MT-Series) specifically for copper slurry pipeline systems.

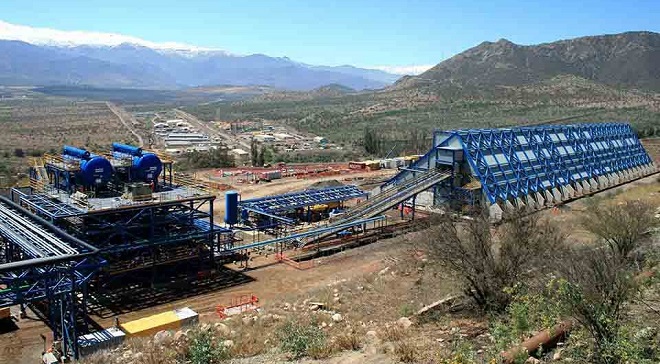

The copper-ore slurry pipeline at Los Bronces’ copper-mine site in Las Tortolas, Chile.

After copper ore is extracted, it undergoes crushing, screening, and grinding to form slurry, a mixture of ore particles and water. This slurry contains a high concentration of solid particles, mainly copper ore fragments, mud, and other impurities. The slurry is transported to the beneficiation plant, where copper concentrate is extracted via flotation, while the remaining solids are discharged as tailings. Copper slurry is usually transported over long distances through pipelines, which are prone to blockages and sedimentation due to the high concentration and abrasive nature of the slurry.

The knife gate valve, with its blade-like gate design, effectively cuts through and passes slurry with a high concentration of solid particles, preventing blockages. In copper slurry pipelines, the roles of knife gate valves are primarily:

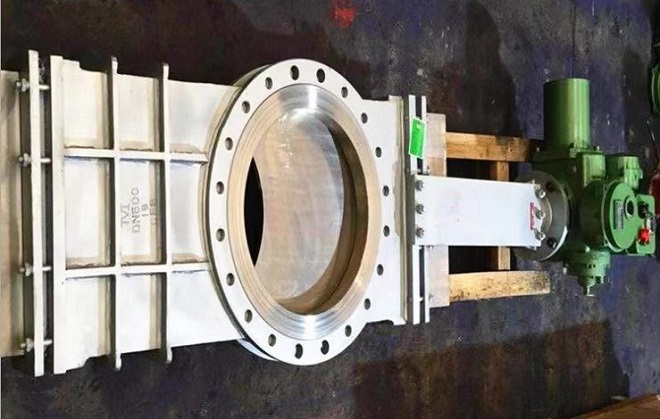

An electric-actuated through conduit knife gate valve for copper mine slurry pipeline systems.

The through-conduit knife gate valve we supply is a knife gate valve where the gate is always in close contact with the valve seat. Its principle is that the gate has a circular hole the same size as the valve’s passage bore. By raising or lowering the gate, the circular hole on the gate either fully disengages or aligns with the valve’s passage bore. The valve chamber of the through-conduit knife gate valve has a minimal gap with the gate, preventing copper slurry from remaining in the valve chamber as the gate moves. The sealing seat features a flexible structure with corrosion resistance and automatic compensation capabilities, which extends the valve’s lifespan. During the opening and closing process, the valve seat remains tightly aligned with the gate, ensuring stable actuation force and effectively cutting off the flow of medium through the valve passage. The through-conduit knife gate valve (MT-Series) can be installed without angle limitations, allowing for convenient operation and adjustable dimensions. This design completely solves installation issues in horizontal, vertical, or any angled pipelines, ensuring no material blockage in copper slurry pipelines.