Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

A single-sphere rubber expansion joint is a non-metallic flexible connector featuring a single long radius arch to absorb various types of movements in piping systems, including axial, lateral, and angular deflections.

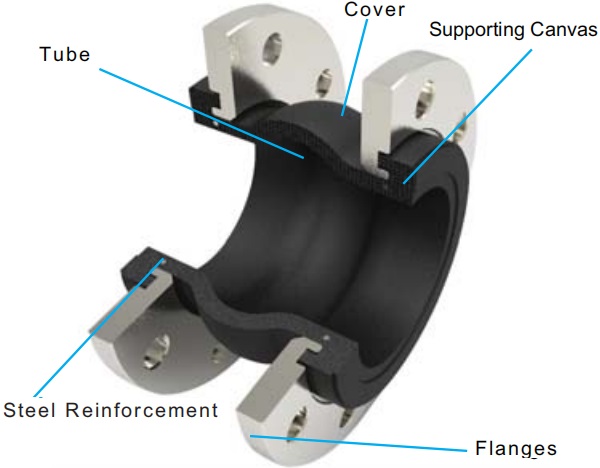

The typical construction of a single-sphere rubber expansion joint.

The single-sphere rubber expansion joint has a molded spherical rubber body, the middle of which resembles a round ball (single sphere). The joint body consists of the inner tube, the carcass made of woven fabric plies or tie cord impregnated with rubber and reinforced by steel wire, and a rubber cover, which are together brought up from the joint body to from a seal bead. Two floating metallic flanges with proper grooves are furnished to accommodate the seal bead at the ends of the joint. The metallic flanges shall be drilled in accordance with the customer order as required, to match the mating flanges in piping systems.

In single-sphere rubber expansion joints, the long-radius contour of the molded spherical body prevents sediment accumulation and creates less turbulence and pressure drop than spool-arch joints. The seal bead at each joint end eliminates any requirement for gaskets between mating flanges. The seal bead is partially recessed into the floating flange when installed, providing a robust and resilient sealing system for the lift of the joint.

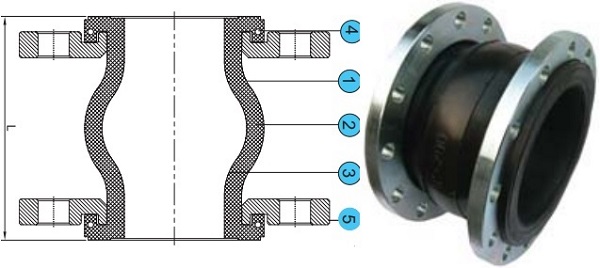

The typical drawing for single-sphere rubber expansion joints.

Single-sphere rubber expansion joints are used across various industries, including: (1) Water and Wastewater Treatment: To manage system vibrations and movements in fluid transport pipes. (2) HVAC Systems: In air conditioning and heating systems to compensate for thermal expansion and minimize noise transmission. (3) Pumping Systems: Near pumps and compressors to absorb vibrations and protect the integrity of the piping. (4) Chemical and Power Plants: To manage thermal expansion and mechanical stress in process piping.

| NPS | L mm | P psi | V mm Hg |

|---|---|---|---|

| 1 | 95 | 16 | 660 |

| 1 1/4 | 95 | 16 | 660 |

| 1 1/2 | 95 | 16 | 660 |

| 2 | 105 | 16 | 660 |

| 2 1/2 | 115 | 16 | 660 |

| 3 | 130 | 16 | 660 |

| 4 | 135 | 16 | 660 |

| 5 | 170 | 16 | 660 |

| 6 | 180 | 16 | 660 |

| 8 | 205 | 16 | 660 |

| 10 | 240 | 10 | 660 |

| 12 | 260 | 10 | 660 |

| 14 | 265 | 10 | 660 |

| 16 | 265 | 7 | 660 |

| 18 | 265 | 7 | 660 |

| 20 | 265 | 7 | 660 |

| 24 | 265 | 7 | 660 |

| 28 | 265 | 7 | 660 |

| 32 | 265 | 7 | 660 |

| 36 | 265 | 7 | 660 |

| 40 | 265 | 7 | 660 |

| 48 | 265 | 7 | 660 |

| NPS | Ac mm | Ae mm | Lt mm | Agu |

|---|---|---|---|---|

| 1 | 6 | 8 | 8 | 15° |

| 1 1/4 | 8 | 4 | 8 | 15° |

| 1 1/2 | 8 | 4 | 8 | 15° |

| 2 | 8 | 5 | 8 | 15° |

| 2 1/2 | 12 | 6 | 10 | 15° |

| 3 | 12 | 6 | 10 | 15° |

| 4 | 18 | 10 | 12 | 15° |

| 5 | 18 | 10 | 12 | 15° |

| 6 | 18 | 10 | 12 | 15° |

| 8 | 25 | 14 | 22 | 15° |

| 10 | 25 | 14 | 22 | 15° |

| 12 | 25 | 14 | 22 | 15° |

| 14 | 25 | 16 | 22 | 15° |

| 16 | 25 | 16 | 22 | 15° |

| 18 | 25 | 16 | 22 | 15° |

| 20 | 25 | 16 | 22 | 15° |

| 24 | 25 | 16 | 22 | 15° |

| 28 | 25 | 16 | 22 | 15° |

| 32 | 25 | 16 | 22 | 12° |

| 36 | 25 | 16 | 22 | 10° |

| 40 | 25 | 16 | 22 | 10° |

| 48 | 25 | 16 | 22 | 8° |

| NPS | L inch | P psi | V mm Hg |

|---|---|---|---|

| 1 | 6 | 225 | 26 |

| 1 1/4 | 6 | 225 | 26 |

| 1 1/2 | 6 | 225 | 26 |

| 2 | 6 | 225 | 26 |

| 2 1/2 | 6 | 225 | 26 |

| 3 | 6 | 225 | 26 |

| 4 | 6 | 225 | 26 |

| 5 | 6 | 225 | 26 |

| 6 | 6 | 225 | 26 |

| 8 | 6 | 225 | 26 |

| 10 | 8 | 150 | 26 |

| 12 | 8 | 150 | 26 |

| 14 | 8 | 150 | 26 |

| 16 | 8 | 150 | 26 |

| 18 | 8 | 150 | 26 |

| 20 | 8 | 150 | 26 |

| 24 | 8 | 150 | 26 |

| NPS | Ac | Ae | Lt | Agu |

|---|---|---|---|---|

| 1 | 1/2" | 3/8" | 1/2" | 15° |

| 1 1/4 | 1/2" | 3/8" | 1/2" | 15° |

| 1 1/2 | 1/2" | 3/8" | 1/2" | 15° |

| 2 | 1/2" | 3/8" | 1/2" | 15° |

| 2 1/2 | 1/2" | 3/8" | 1/2" | 15° |

| 3 | 1/2" | 3/8" | 1/2" | 15° |

| 4 | 5/8" | 3/8" | 1/2" | 15° |

| 5 | 5/8" | 3/8" | 1/2" | 15° |

| 6 | 5/8" | 3/8" | 1/2" | 15° |

| 8 | 5/8" | 3/8" | 1/2" | 15° |

| 10 | 3/4" | 1/2" | 3/4" | 15° |

| 12 | 3/4" | 1/2" | 3/4" | 15° |

| 14 | 3/4" | 1/2" | 3/4" | 15° |

| 16 | 3/4" | 1/2" | 3/4" | 15° |

| 18 | 3/4" | 1/2" | 3/4" | 15° |

| 20 | 3/4" | 1/2" | 3/4" | 15° |

| 24 | 3/4" | 1/2" | 3/4" | 15° |

| Specification of Rubber Expansion Joints | ||

|---|---|---|

| Single Sphere | Twin Sphere | Union Spherical |

| Spool Arch | Tie Rods | Special Design |

| Flange Drilling | Installation & Maintenance | Testing & Inspection |