Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

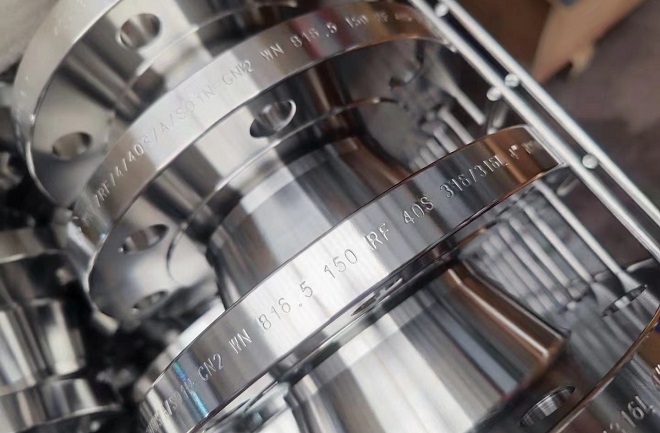

ASTM A182 F316/ F316L dual certified flanges, 4″ WNRF SCH40S.

ASTM A182 F316 and F316L are both grades of forged stainless steel flanges commonly used in process piping according to ASME B31.3, in which corrosive environments are involved. ASTM A182 Grade F316 is a standard molybdenum-bearing austenitic stainless steel with a higher chromium content than F304, providing improved corrosion resistance, particularly against chloride ion corrosion. F316 flanges are known for their excellent mechanical properties, including high tensile strength, good ductility, and toughness, making them suitable for a wide range of applications. ASTM A182 Grade F316L is a low-carbon variant of F316, characterized by its reduced carbon content, typically less than 0.03%, which enhances its weldability and corrosion resistance, especially in sensitization-prone environments. F316L flanges offer improved resistance to intergranular corrosion due to carbide precipitation during welding or exposure to high temperatures. On the other hand, F316 flanges exhibits higher strength due to the higher carbon content, thus, can withstand higher stress or pressure in service.

ASTM A182 F316L flanges packaged in a wooden case, supplied to Chile.

The ASME B31.3 is an international piping code released by The American Society of Mechanical Engineers. The process piping refers to piping typically found in petroleum refineries; onshore and offshore petroleum and natural gas production facilities; chemical, pharmaceutical, textile, paper, ore processing, semiconductor, and cryogenic plants; food and beverage processing facilities; and related processing plants and terminals.

Due to the higher carbon content, ASTM A182 F316 flanges usually has higher strength and better creep strength than F316L flanges. This is mainly because of the interstitial strengthening effect by carbon atoms in the stainless steel. In stainless steel F316 and F316L, carbon combines with chromium to form chromium carbides. The higher carbon content of F316 allows for more chromium carbide formation, which contributes to the steel’s strength by reinforcing the metallic matrix. This increased strength is reflected in higher allowable stress values, as the material can withstand greater forces without yielding or deforming. According to the process piping Code of ASME B31.3, both F316 and F316L flanges can be used at the maximum temperature of 1500°F, however, the allowable stress of F316 is relatively higher than that of F316L at the same temperature.

| *Temp. °F | *S F316L psi | *S' F316 psi |

|---|---|---|

| 100 | 16.7 | 20.0 |

| 200 | 16.7 | 20.0 |

| 300 | 16.7 | 20.0 |

| 400 | 15.7 | 19.3 |

| 500 | 14.8 | 18.0 |

| 600 | 14.0 | 17.0 |

| 650 | 13.7 | 16.6 |

| 700 | 13.5 | 16.3 |

| 750 | 13.2 | 16.1 |

| 800 | 12.9 | 15.9 |

| 850 | 12.7 | 15.7 |

| 900 | 12.4 | 15.6 |

| 950 | 12.1 | 15.4 |

| 1000 | 11.8 | 15.3 |

| 1050 | 10.8 | 15.1 |

| 1100 | 10.2 | 12.4 |

| 1050 | 8.8 | 9.8 |

| 1200 | 6.4 | 7.4 |

| 1250 | 4.7 | 5.5 |

| 1300 | 3.5 | 4.1 |

| 1350 | 2.5 | 3.1 |

| 1400 | 1.8 | 2.3 |

| 1450 | 1.3 | 1.7 |

| 1500 | 1.0 | 1.3 |