Categories

- Pipe & Tube (18)

- Flange & Fitting (97)

- Fastener & Gasket (12)

- Valve & Pump (18)

- Base Material (11)

- Equipment (8)

- Application (30)

- Technical (110)

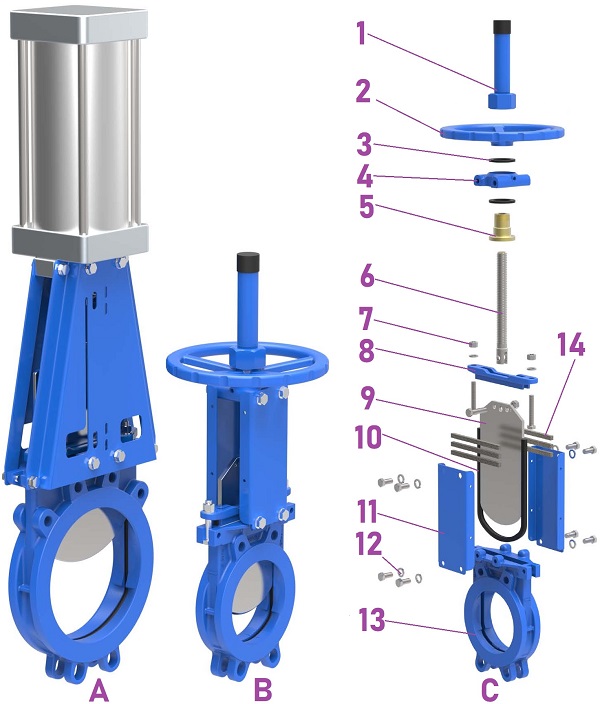

The MR-series resilient seat bidirectional knife gate valves: A – pneumatic actuation, B – rising stem with handwheel, C – 3D explosive view of the resilient seated knife gate valve.

The MR-series knife gate valves are resilient-seated bidirectional valves. They are one of the most popular family member of knife gate valves, which have several distinctive design characteristics: (1) One-Piece body design: The valve body is cast as a whole, with grooves on the left and right sides as well as the bottom of the valve body cavity. (2) U-type resilient seat design: The U-type resilient seat is mounted in the grooves of the body cavity. When the valve is closed, the disc moves down. The bottom edge of the disc is in close contact with the resilient seat, which is then completely compressed into the groove of the body cavity to achieve the zero-leakage sealing tightness. When the knife gate valve is opened, the disc moves up. The bottom edge of the disc separates from the sealing surface, and the U-type seat bounces up to be level with the groove in the body cavity. (3) Bidirectional flow: It allows the flow of fluids to pass through the valve in either direction, providing greater flexibility and versatility for flow control in a wide range of applications. (4) Self-cleaning flow passage: Thanks to the “bouncing back” mechanism of the resilient U-type seat, when the MR-series knife gate valve is opened, the seat itself automatically clean the full-port flow passage within the body cavity. No fluid/slurry residue will be retained by the cavity grooves, thus, the valve is free from clogging or leakage. (5) Multiple actuation or operation methods available: handwheel, gear box, lever, pneumatic, electric, and hydraulic. (6) Design standard: MSS SP 81. (7) Pressure ratings: PN2.5, PN6, PN10, PN16, Class 150, 75 psi, 150 psi, 300 psi. (8) Size range: DN50 ~ DN1400.

| Part No. | Part Name | Material Grade |

|---|---|---|

| 1 | Stem Cover | Mild Steel |

| 2 | Handwheel | ASTM A216 WCB GGG40 |

| 3 | Bearings | ZChSnSb10-6 |

| 4 | Yoke Head | ASTM A216 WCB GGG40 |

| 5 | Stem Nut | Brass |

| 6 | Stem | 2Cr13/ SS410 SS304/ SS316 |

| 7 | Bolts & Nuts | SS201/ SS304 |

| 8 | Packing Gland | GGG40, WCB CF8, CF8M |

| 9 | Disc | SS304/ SS304L SS316/ SS316L Duplex 2205 |

| 10 | U-type Seat | FKM, NBR EPDM, SBR Polyurethane |

| 11 | Yokes | Mild Steel SS304 |

| 12 | Bolts & Nuts | SS201/ SS304 |

| 13 | Body | GGG40, WCB CF8, CF8M CF3, CF3M Duplex 2205 |

| 14 | Packing | PTFE, NBR |

The material grade of each valve part of the MR-series knife gate valve shall be determined based on the following factors: (1) Operation conditions: working temperature, working pressure, fluid media type and concentration, as well as ambient conditions. (2) Industrial standards and design codes. (3) Corrosion resistance requirements. (4) Abrasion resistance requirements. (5) Mechanical properties. (6) Cost.

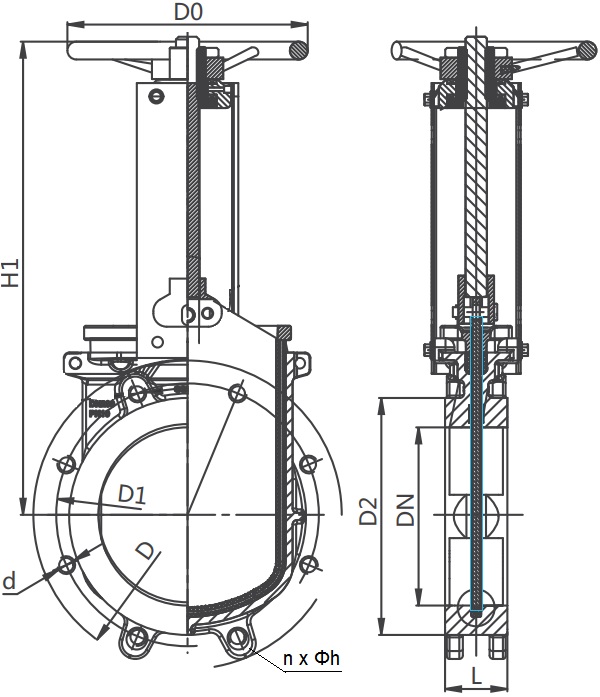

The G.A. drawing of MR-series resilient-seated knife gate valves, handwheel operated for universal purpose.

| Size | L | H1 | Do |

|---|---|---|---|

| 2" | 48 | 260 | 180 |

| 2-1/2" | 48 | 292 | 200 |

| 3" | 51 | 320 | 200 |

| 4" | 51 | 358 | 240 |

| 5" | 57 | 395 | 260 |

| 6" | 57 | 450 | 280 |

| 8" | 70 | 532 | 300 |

| 10" | 70 | 670 | 320 |

| 12" | 76 | 758 | 350 |

| 14" | 76 | 875 | 400 |

| 16" | 89 | 946 | 450 |

| 18" | 89 | 1023 | 500 |

| 20" | 114 | 1230 | 500 |

| 22" | 114 | Gear | Gear |

| 24" | 114 | Gear | Gear |

| 26" | 114 | Gear | Gear |

| 28" | 127 | Gear | Gear |

| 30" | 127 | Gear | Gear |

| 32" | 127 | Gear | Gear |

| 34" | 127 | Gear | Gear |

| 36" | 127 | Gear | Gear |

| 38" | 149 | Gear | Gear |

| 40" | 149 | Gear | Gear |

| 42" | 149 | Gear | Gear |

| 44" | 149 | Gear | Gear |

| 46" | 149 | Gear | Gear |

| 48" | 156 | Gear | Gear |

| 50" | 156 | Gear | Gear |

| 52" | 156 | Gear | Gear |

| 54" | 171 | Gear | Gear |

| 56" | 171 | Gear | Gear |

The drilling dimensions of MR-series resilient-seated knife gate valves may be provided in accordance with JIS B2220 10K, 16K; GB/BS4505/EN1092-1/DIN PN2.5, PN2.5, PN6, PN10, PN16; ASME B16.5 Class 150; BS10 Table D, Table E; GOST 12820-80 PN1.0 & PN1.6.