Product Categories

- Products (61)

A PTFE lined lug type butterfly valve, bare stem, BS 5155 PN16, integrally cast ductile iron body, PTFE+EPDM composite seat, PTFE encapsulated disc.

A lug type butterfly valve, ductile iron body and worm gear operated, PTFE lined seat & PTFE encapsulated disc, spilt body (two-piece).

PTFE (polytetrafluoroethylene) is a linear crystalline polymer with a melting point of 327°C. The PTFE linings used for butterfly valves have excellent corrosion resistance to most chemicals covering most organic and inorganic acids and alkalis. Only alkali metals in molten state may attack the polymer. PTFE does not absorb significant quantities of water and has low permeability to gases and moisture vapor. It is a tough polymer with good insulating properties. It is also known for its low coefficient of friction and self-lubricating tendency, with values in the range of 0.02 to 0.10. Thus, PTFE linings can significantly reduce the operating torque of the valve. PTFE, like other fluoropolymers, has excellent heat resistance and can withstand temperatures up to 260°C. Because of the high thermal stability, the mechanical and electrical properties of PTFE remain stable for long times at temperatures up to 250°C. In addition to its high temperature resistance, PTFE has very good toughness and flexibility at low temperatures down to -195°C. PTFE also has good strength and ductility, with tensile strength over 22.5 MPa and elongation rate over 250%.

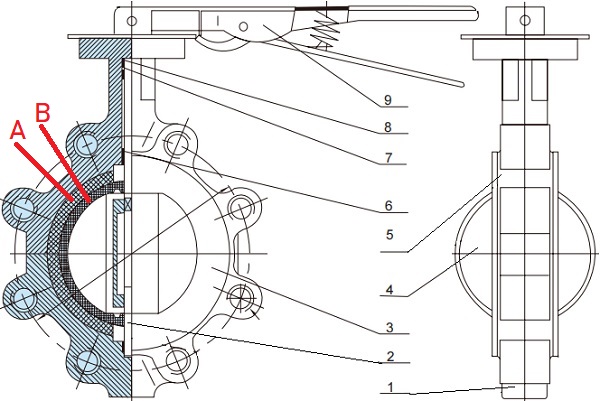

The technical G.A. drawing for a fully PTFE lined lug-type butterfly valve, integrally cast ductile iron body, handle operated.

The fully PTFE lined lug-type butterfly valve has the following design features: (1) Composite seat made of PTFE and EPDM. As illustrated the G.A. drawing, the outer layer A is the EPDM rubber seat that provides sufficient elasticity; the inner layer B is the PTFE lining that provides superior corrosion resistance and low friction. (2) PTFE encapsulated disc ensures that all wetted surfaces in contact with the fluid are PTFE. (3) The lug-type valve body can be either integrally cast or split body with upper and lower two halves. (4) ISO 5211 mounting flange for multiple operators: handle lever, electric actuator, pneumatic actuator, electric & hydraulic actuator, worm gear.

| Item | Main Part | Material |

|---|---|---|

| 1 | Lower Body | Ductile Iron |

| 2 | Shaft | SS 304, SS 316 SS 410, SS 431 Al-Bronze |

| 3 | Seat | EPDM+PTFE |

| 4 | Disc | D.I.+PTFE |

| 5 | Upper Body | Ductile Iron |

| 6 | Bushing | PTFE |

| 7 | O-ring | EPDM, Viton |

| 8 | Bushing | PTFE |

| 9 | Handle | Malleable Iron |

| NPS | H1 mm | H2 mm | C mm | L mm |

|---|---|---|---|---|

| 1-1/2" | 68 | 110 | 24 | 33 |

| 2" | 80 | 161 | 30 | 42 |

| 2-1/2" | 89 | 175 | 30 | 45 |

| 3" | 95 | 181 | 30 | 45 |

| 4" | 114 | 200 | 30 | 51 |

| 5" | 127 | 213 | 30 | 55 |

| 6" | 139 | 226 | 30 | 55 |

| 8" | 175 | 260 | 34 | 60 |

| 10" | 203 | 292 | 34 | 67 |

| 12" | 242 | 337 | 34 | 76 |

| 14" | 267 | 368 | 40 | 76 |

| 16" | 316 | 400 | 52 | 102 |

| 18" | 334 | 422 | 52 | 114 |

| 20" | 370 | 480 | 64 | 127 |

| 22" | 433 | 533 | 70 | 151 |

| 24" | 468 | 562 | 70 | 151 |

| 26" | 484 | 540 | 70 | 172 |

| 28" | 530 | 626 | 95 | 165 |

| 32" | 675 | 602 | 95 | 190 |

| 40" | 810 | 724 | 130 | 216 |

Design standards: MSS SP 67, API 609, BS 5155, EN 593, DIN 3202. Design pressure ratings: Class 125, Class 150, PN 10, PN 16. Working temperature range: -10°C to 250°C.